Hi

I'm here again after a long illness vacation.

My SAK SAK 800D CASE was completed.

http://www.hardwareluxx.de/communit...-watercooled-copper-acrylic-pipe-1028332.html

Final Photos of MAC G5 CASE are comng soon.

http://www.hardwareluxx.de/community/f143/mac-g5-mod-arg-ist-1050219.html

And it is time to begin with a new Mod.

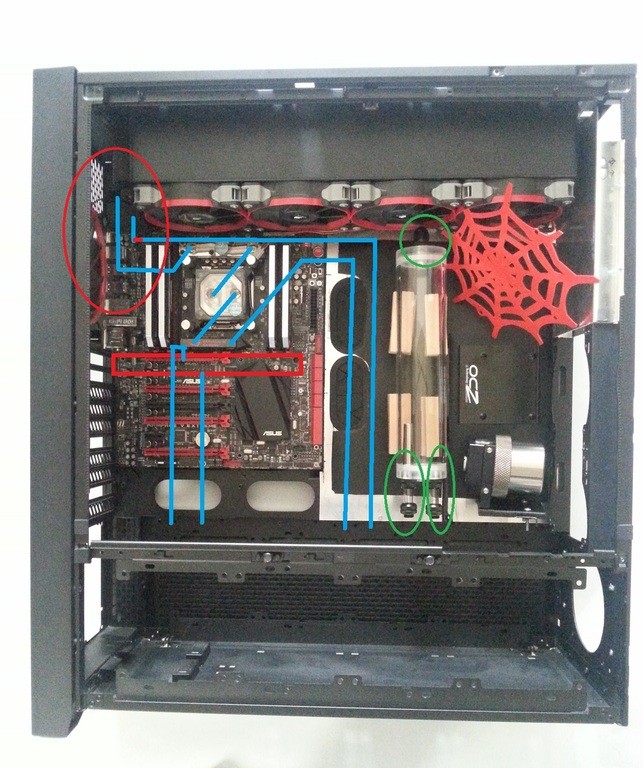

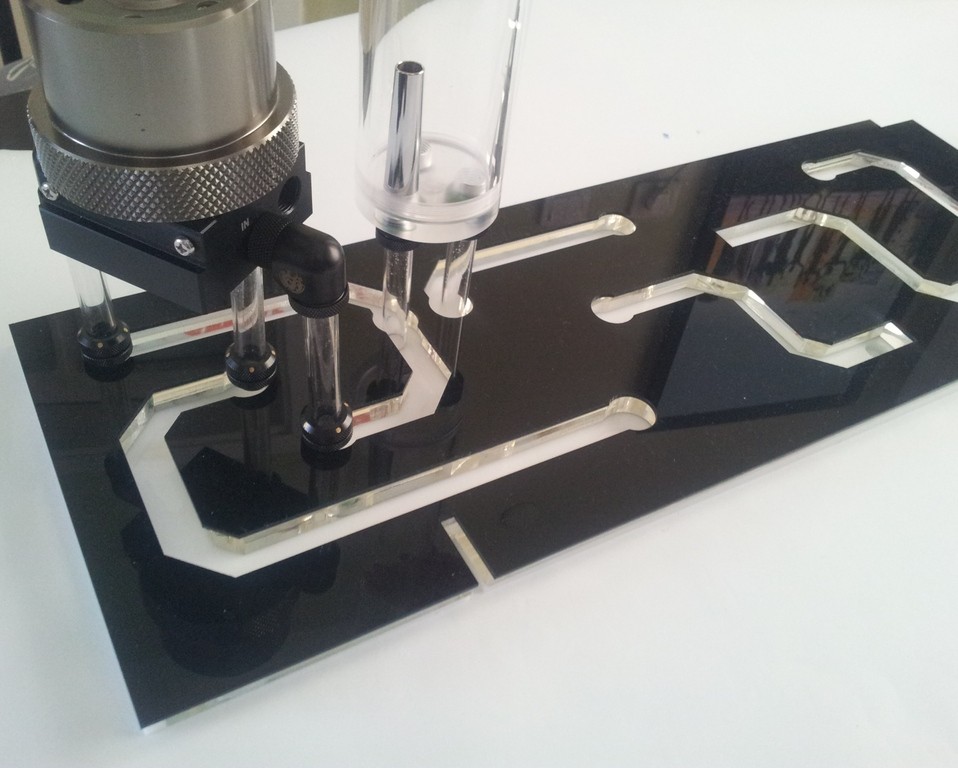

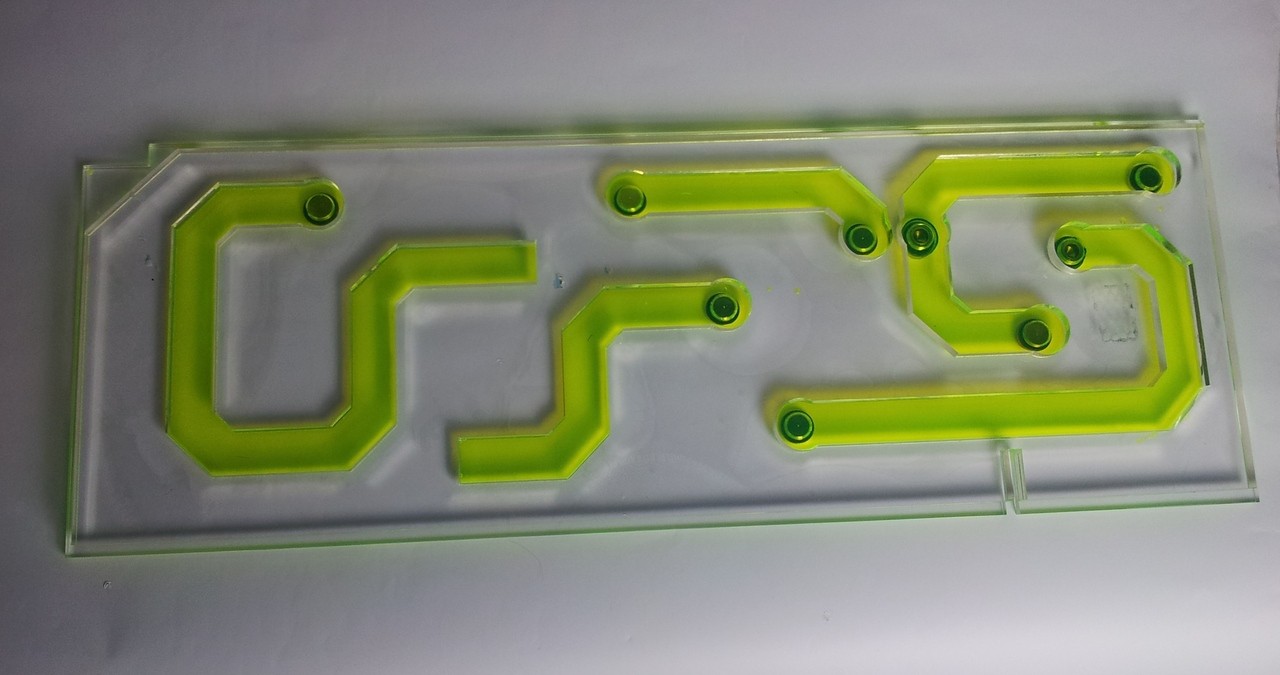

12 Angry Men SPIDER WEB Case

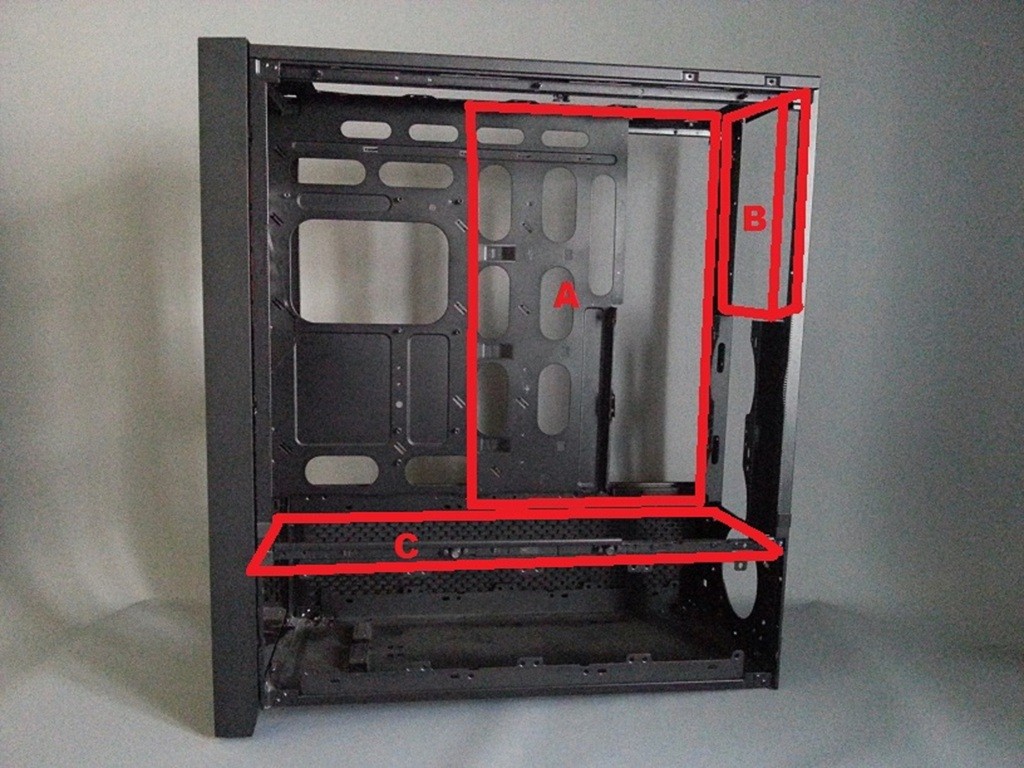

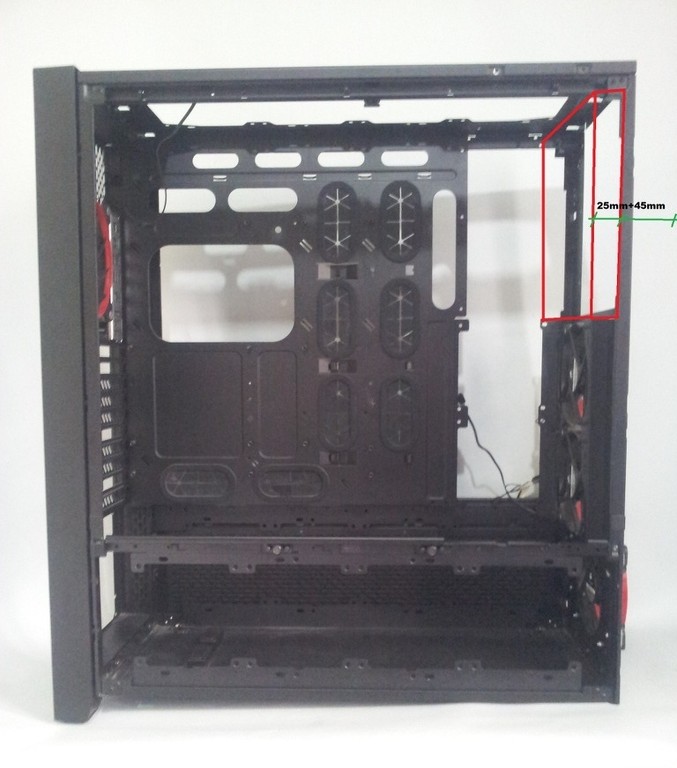

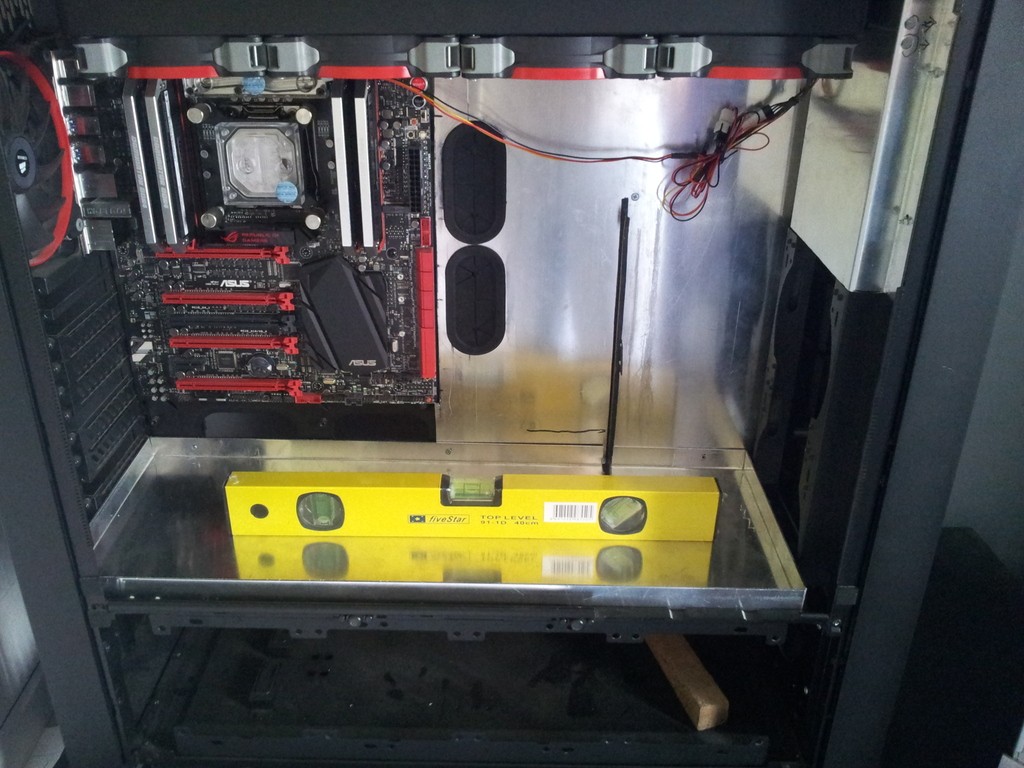

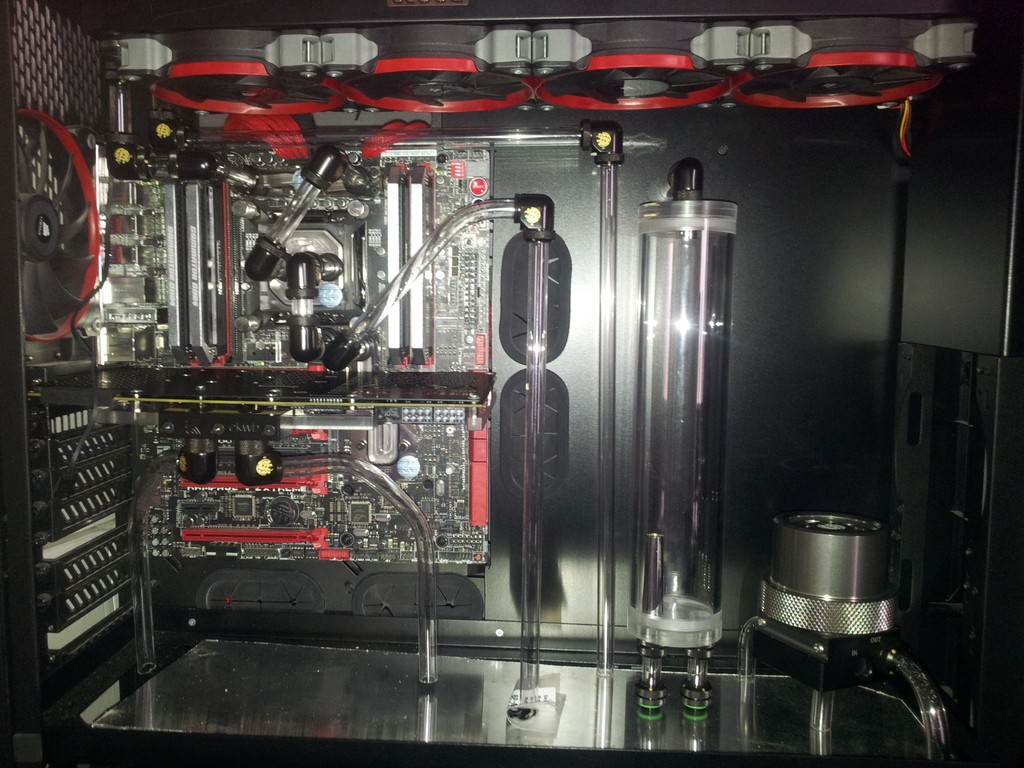

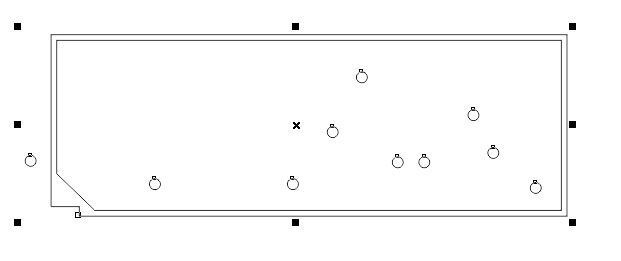

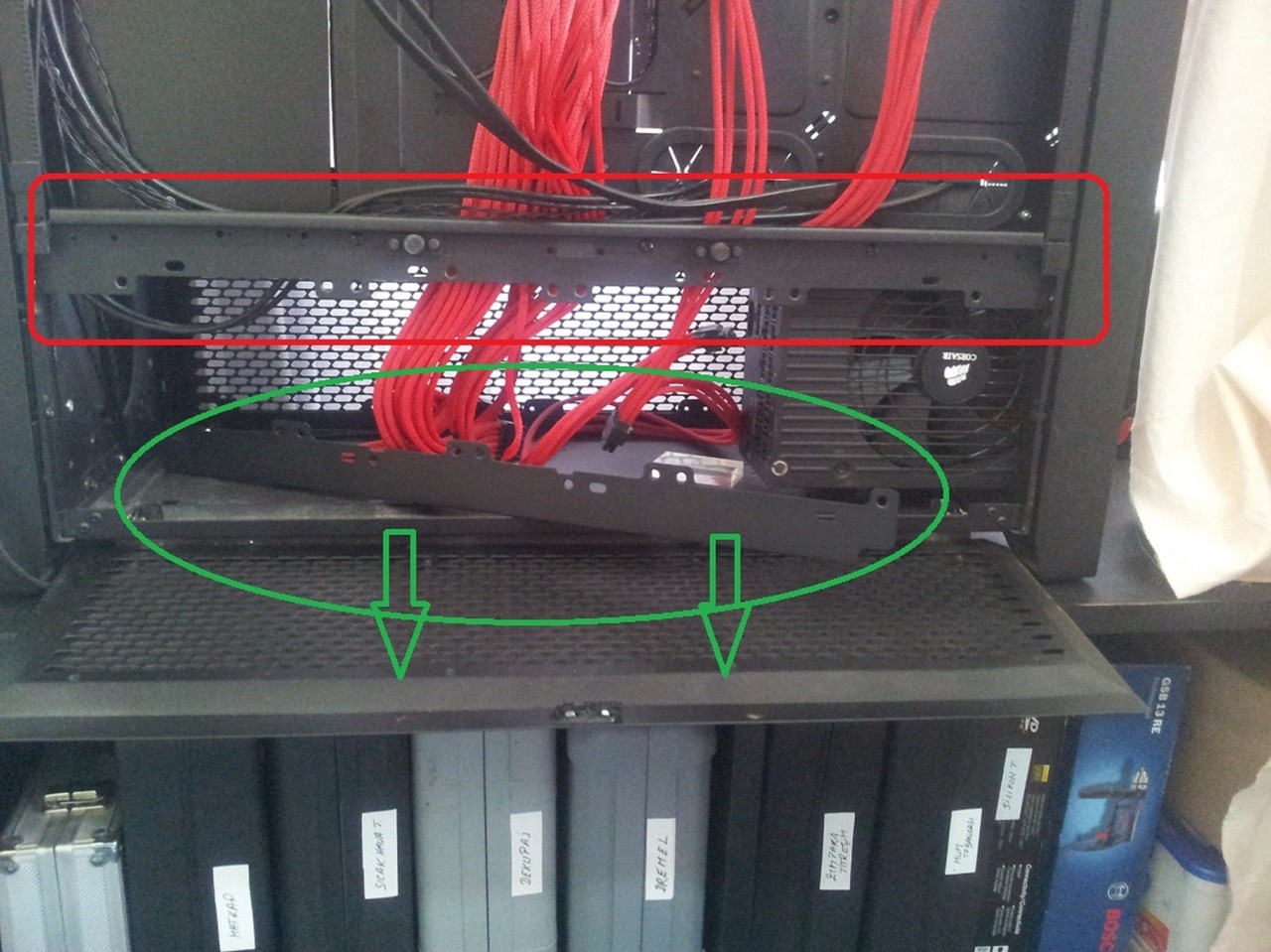

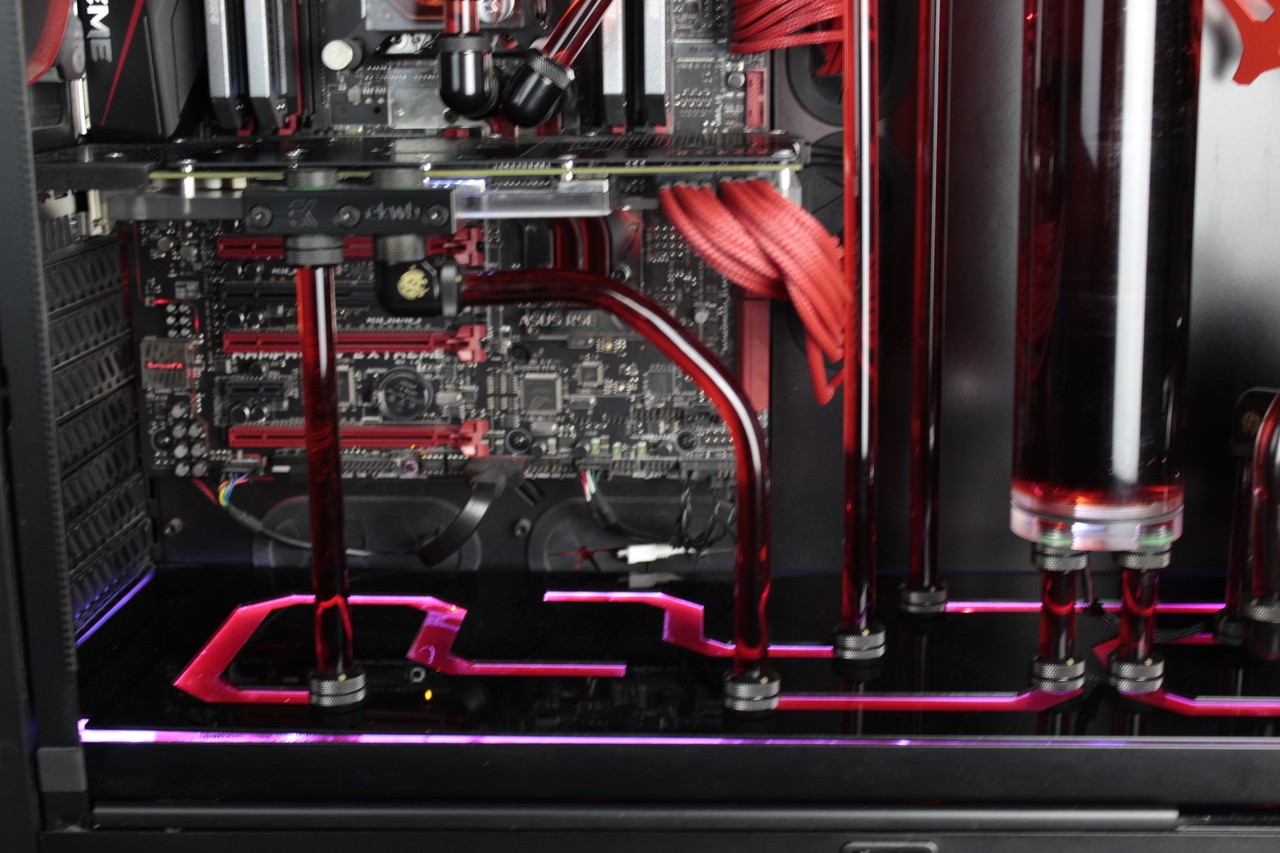

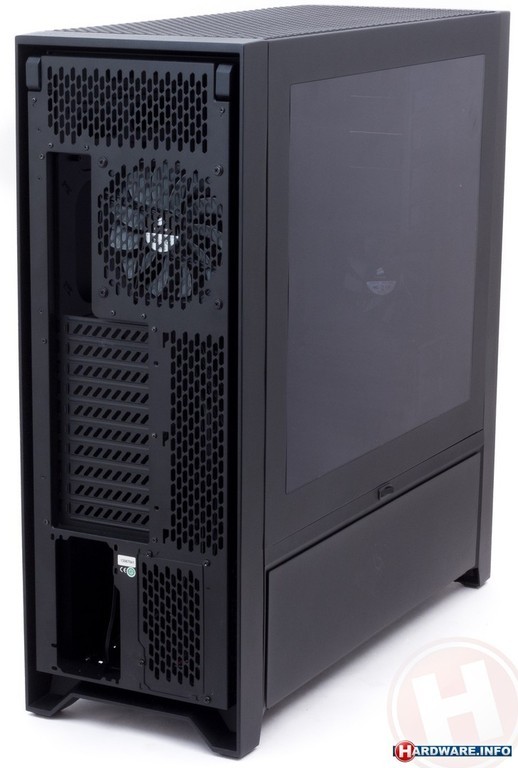

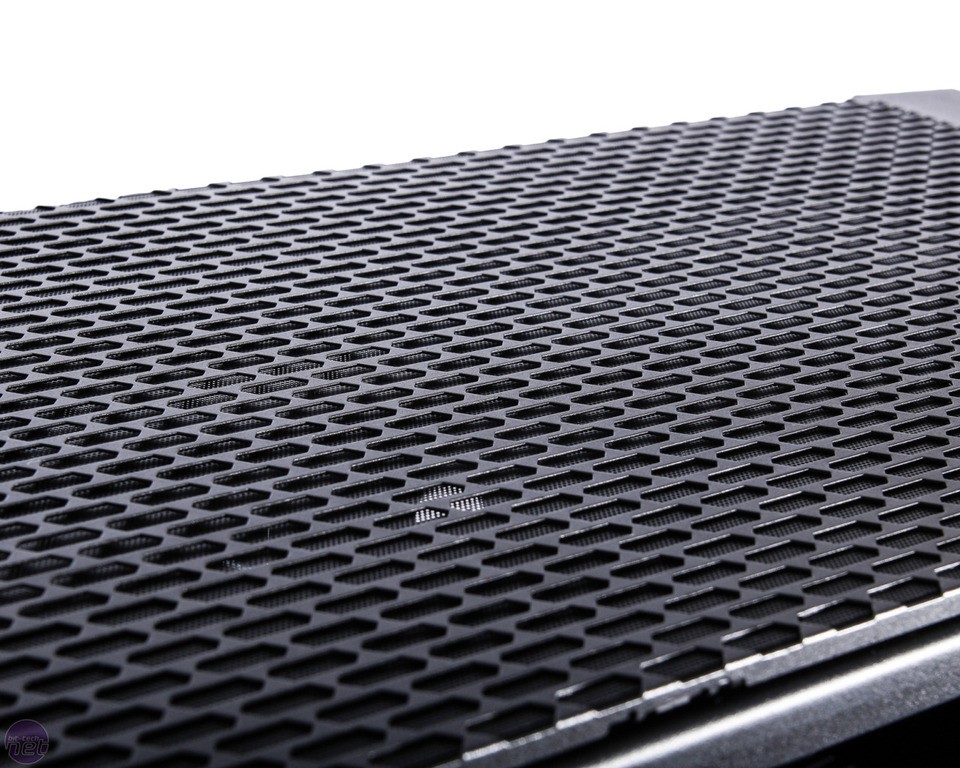

Again a 900D case… A nice case but with some with some shortcomings and errors. I do not know how many 900D case it was.

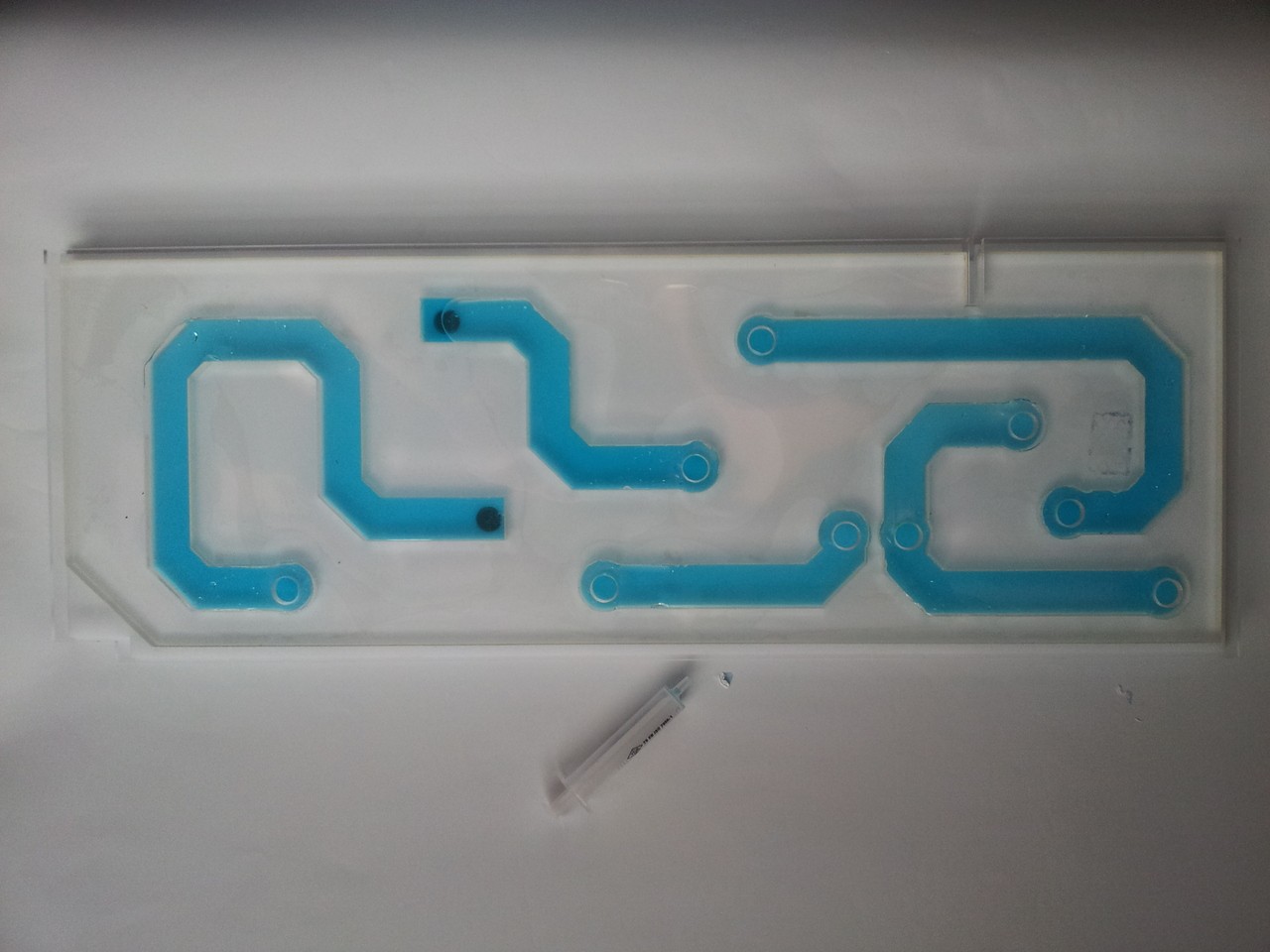

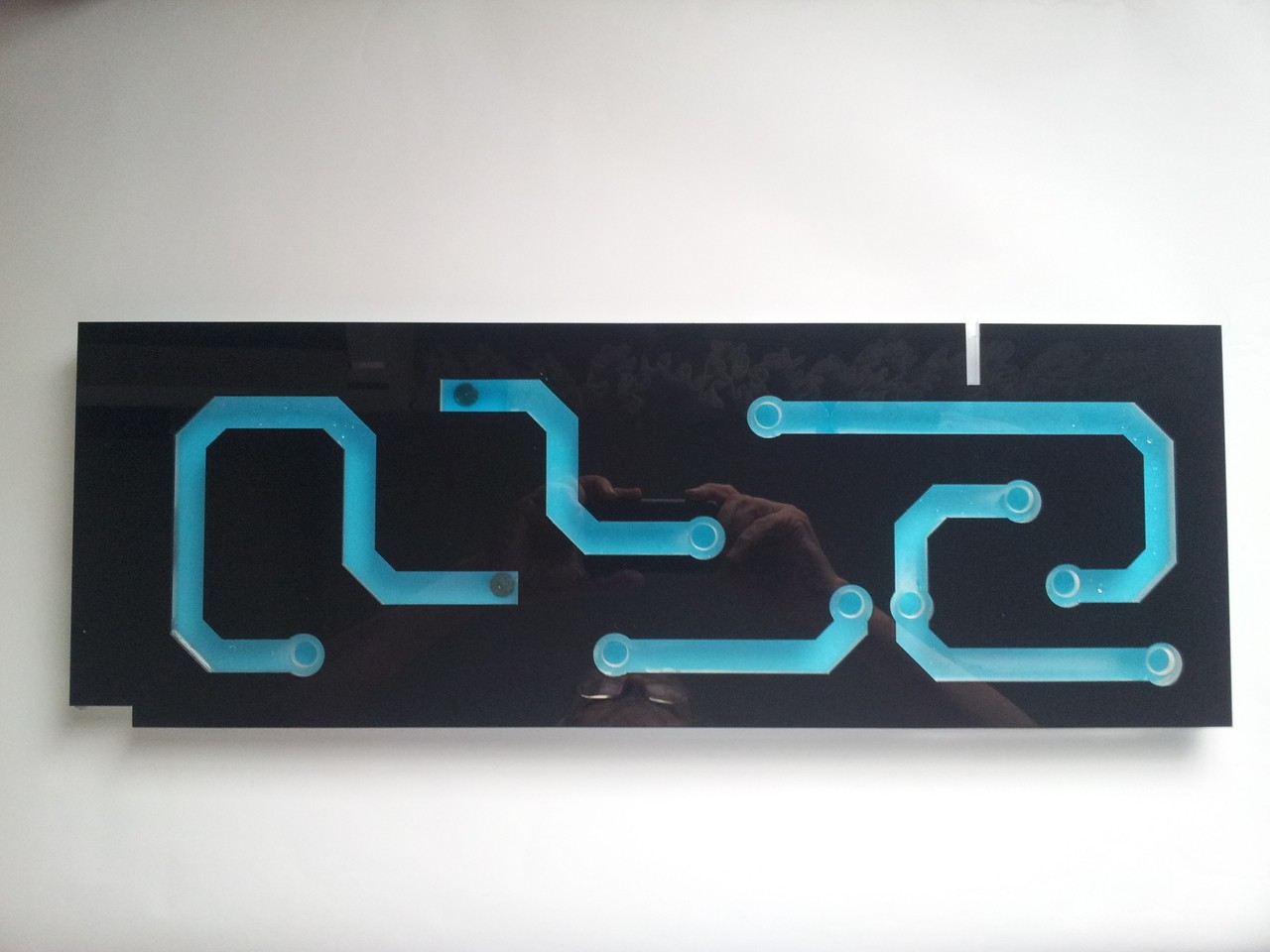

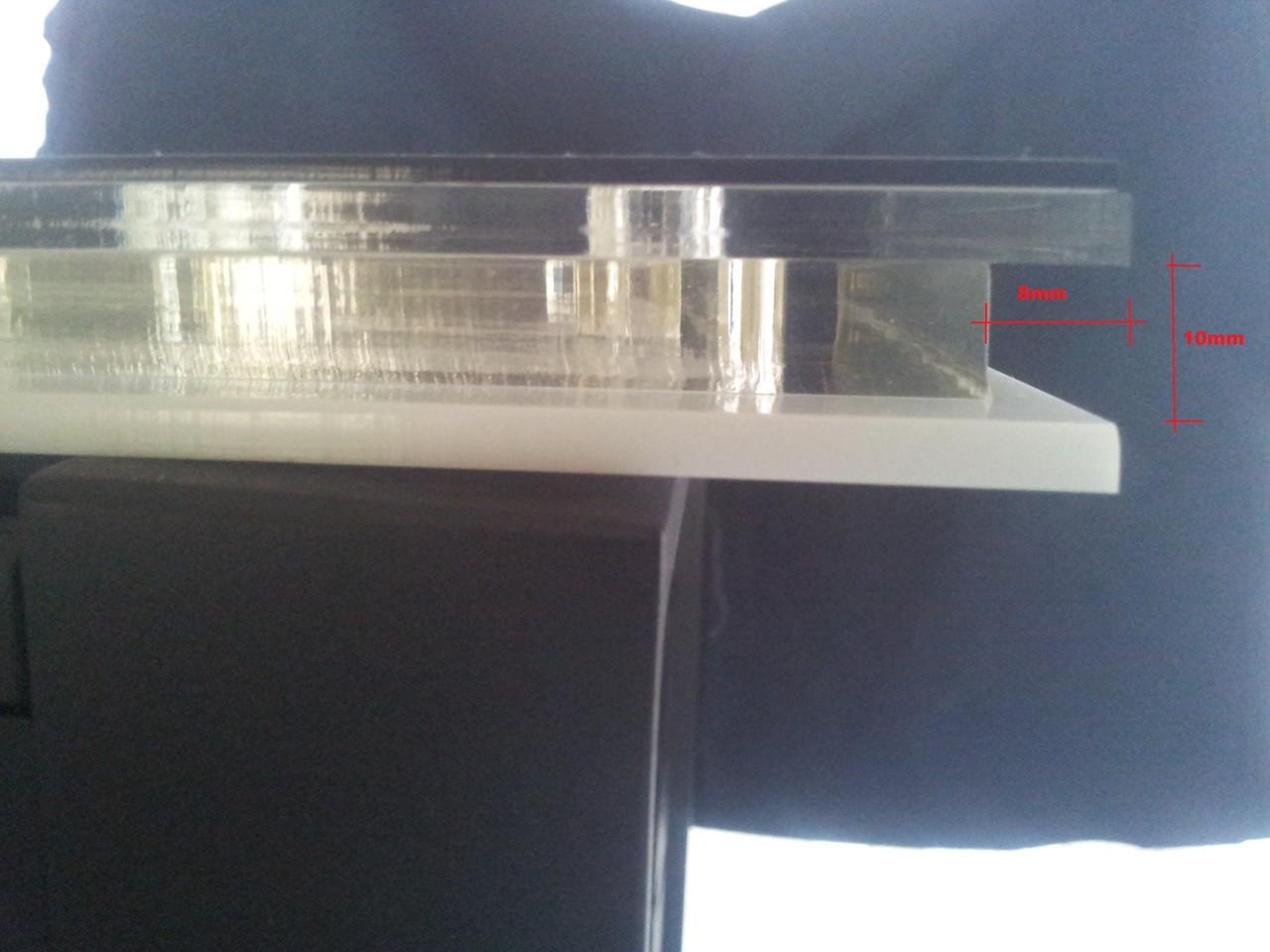

With the theme SPIDER WEB CASE.

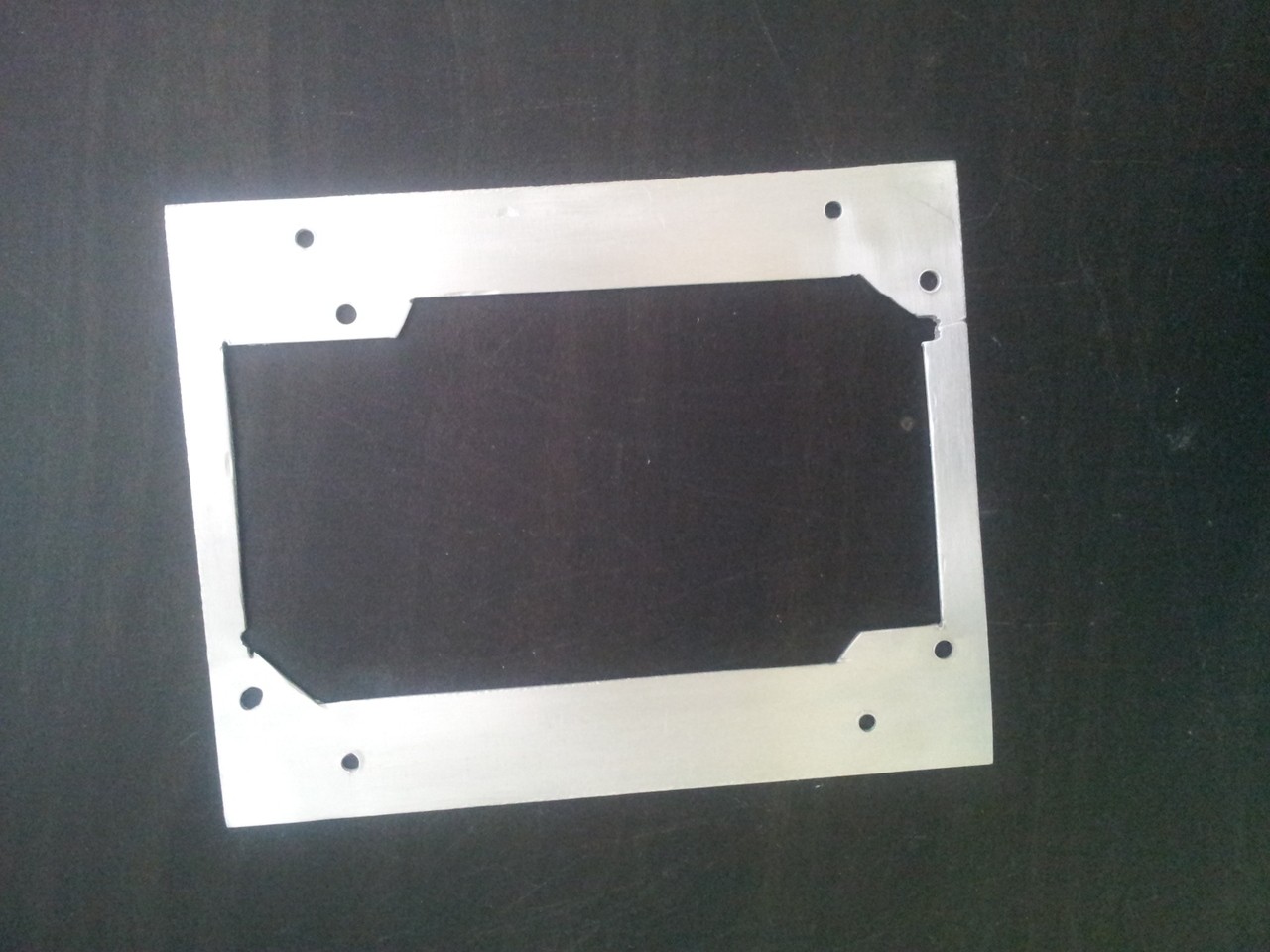

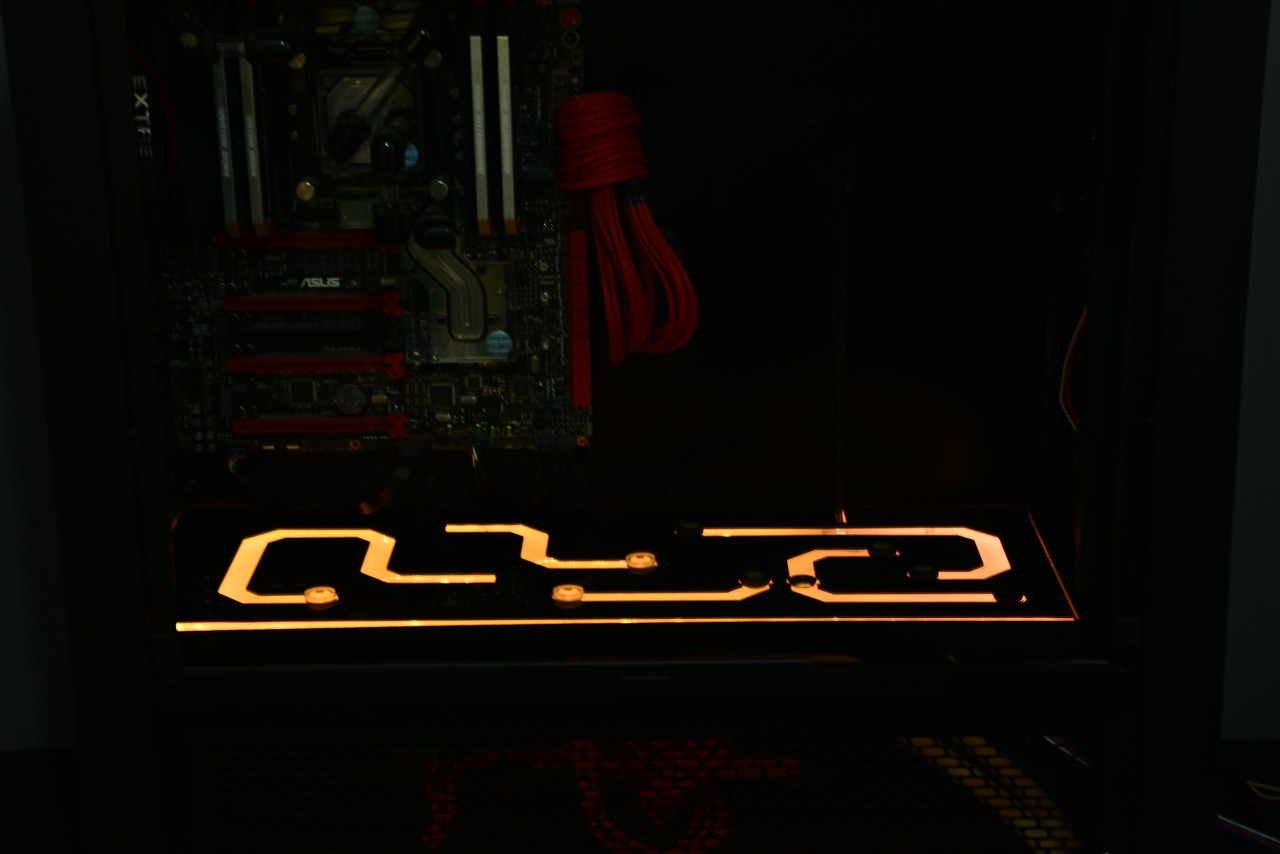

A1-

A2-

A3-

A4-

A5-

A6-

A7-

A8-

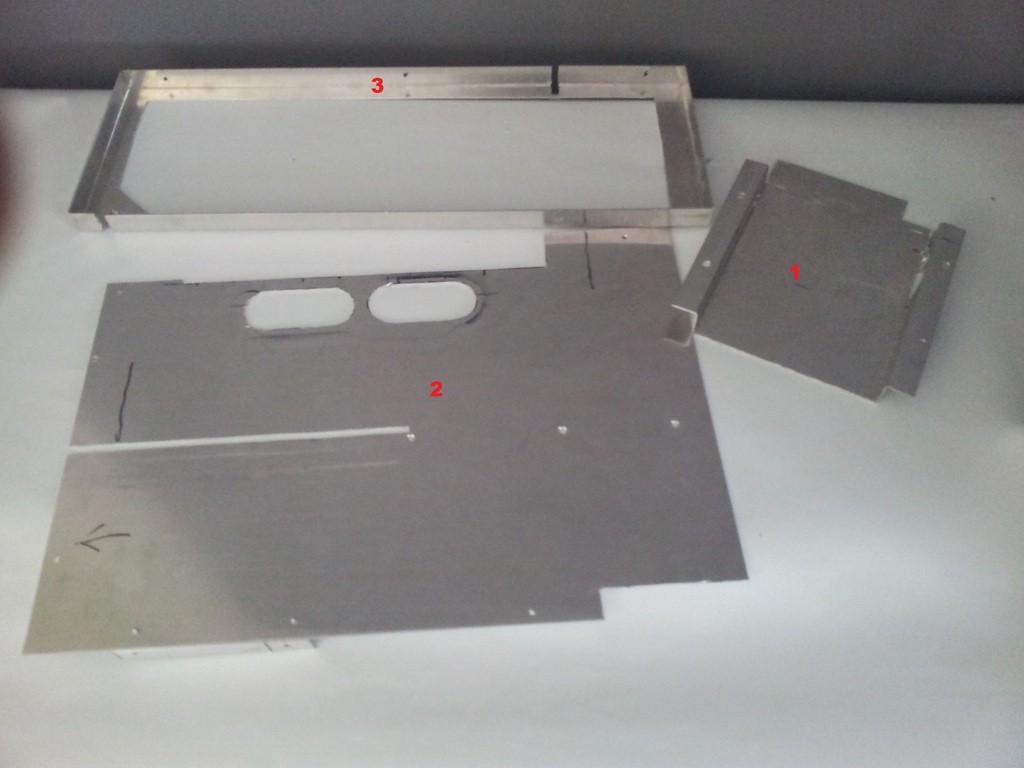

materials used at this case

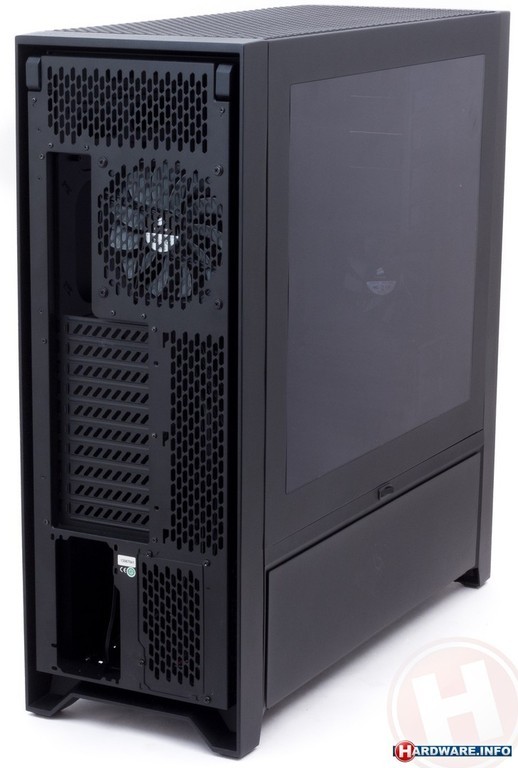

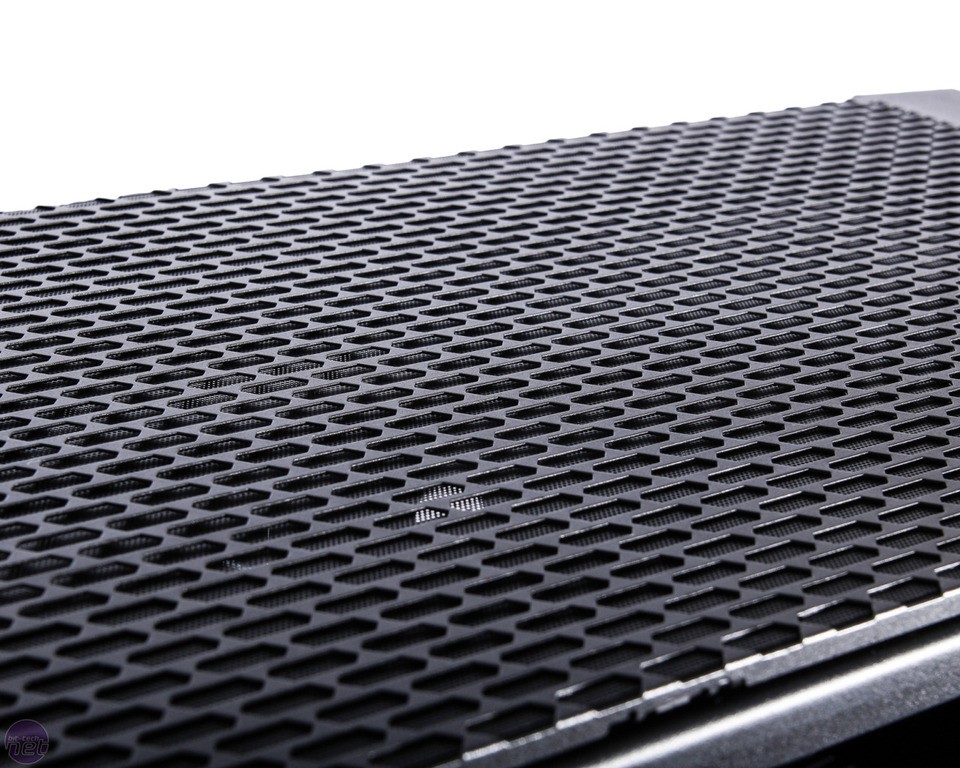

CASE : Corsair 900D

D2

MB : Asus Rampage 5 extreme

D 10

CPU: İNTEL 5820 K

D14

RAM: CORSAIR DOMİNATOR PLATİNUM 4X8GB 3000

D13

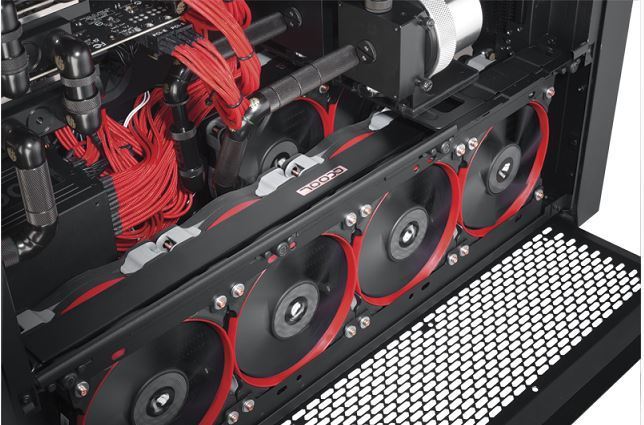

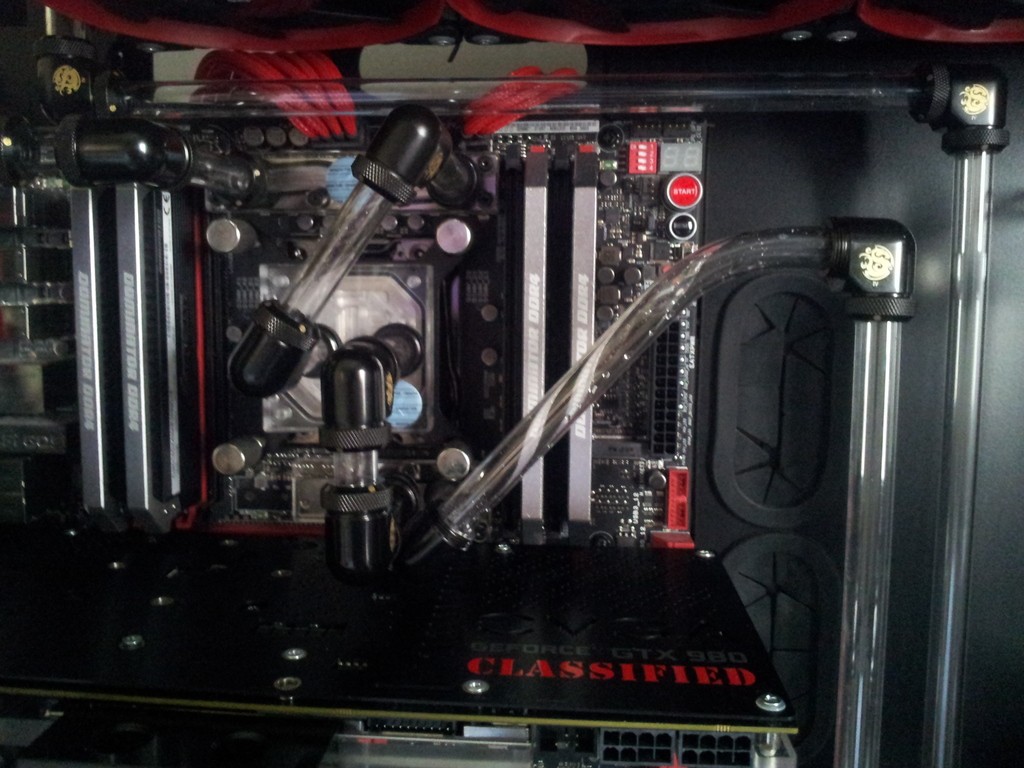

VIDEO CARD :Evga 980 Classified

D8

D9

WATERCOOLING PARTS

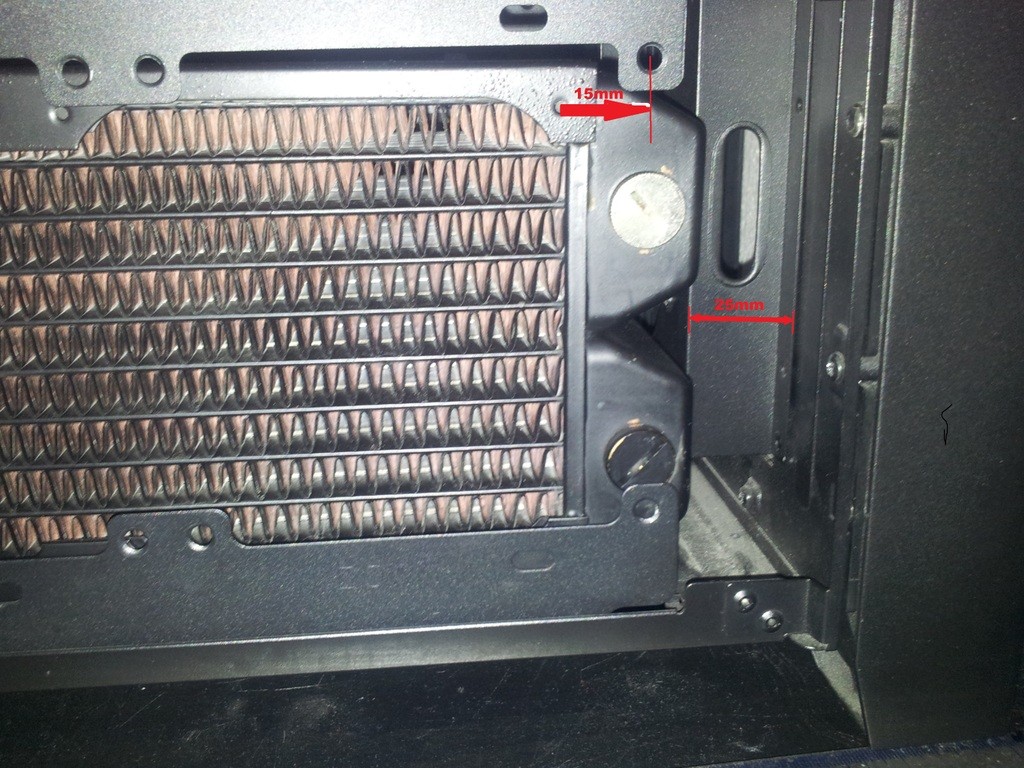

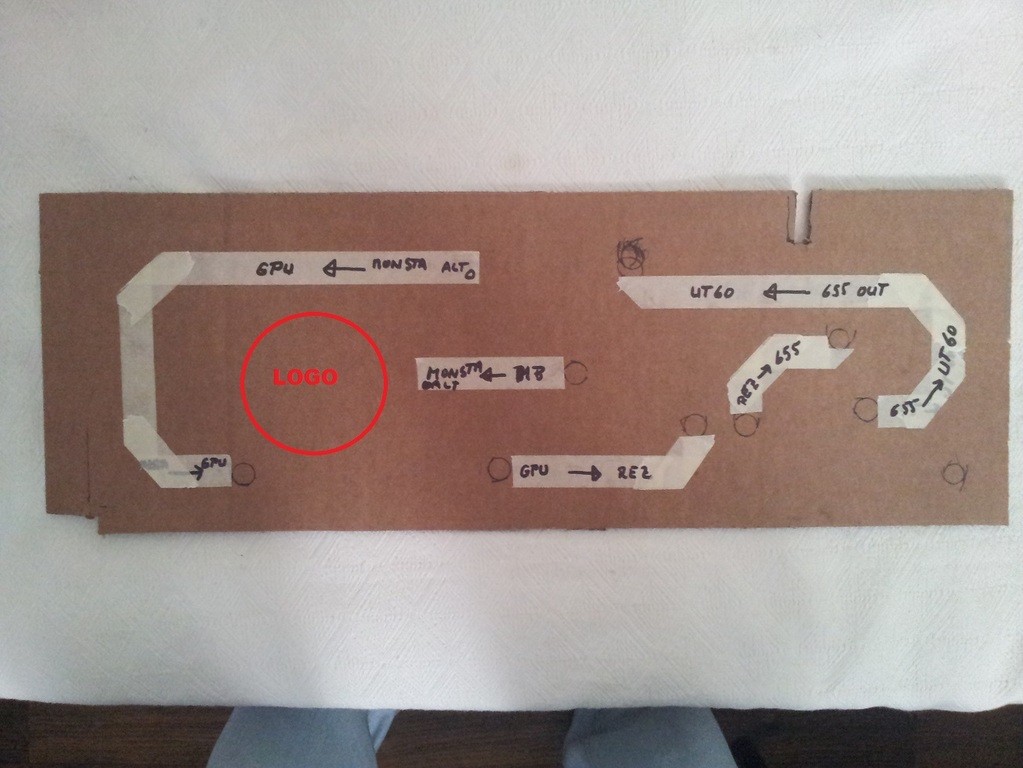

RADIATORS: Alphacool UT60 480

Alphacool Monsta 480

D1

WB: EK

FITTINGS:

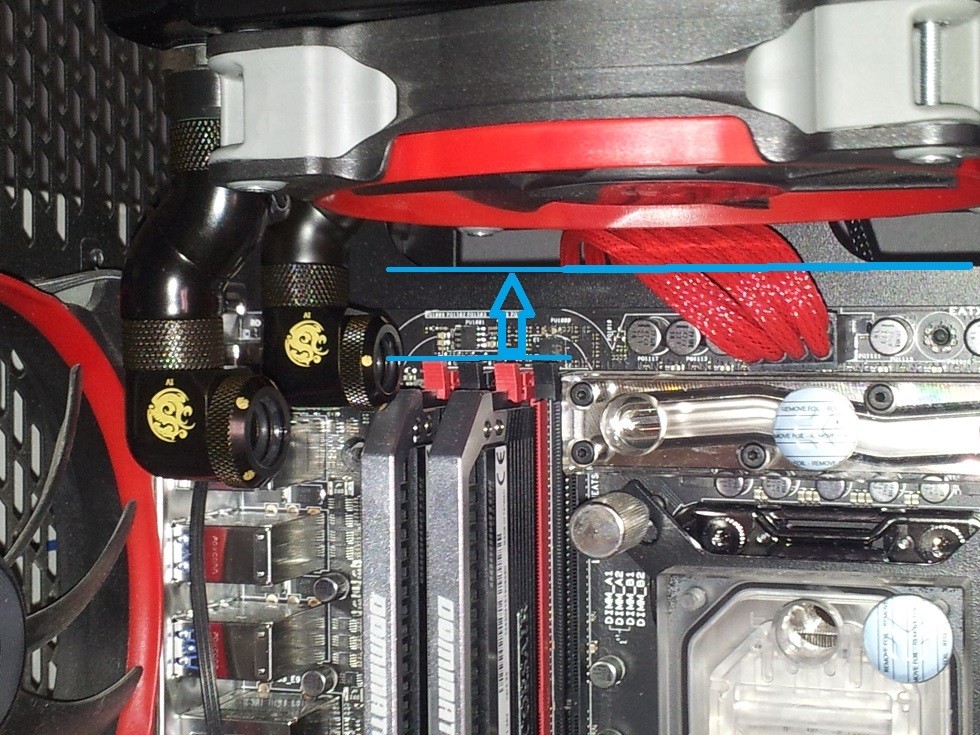

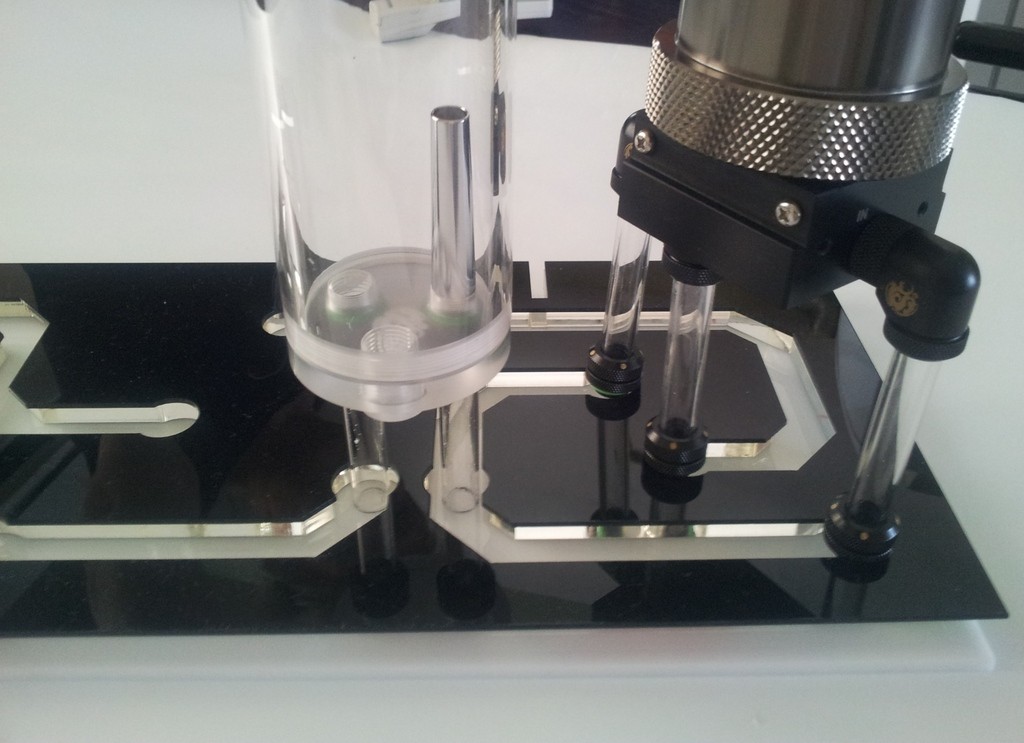

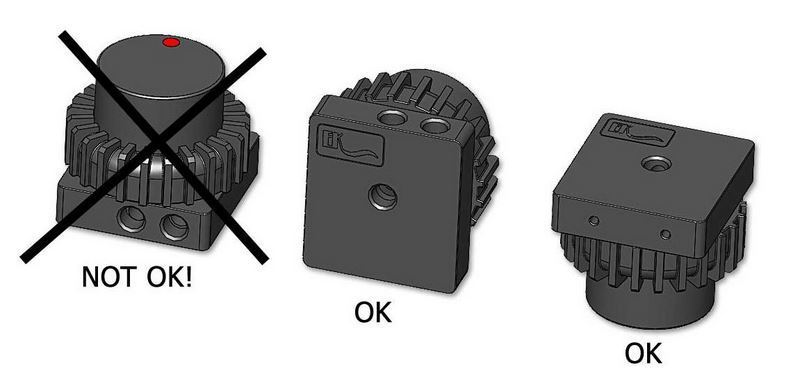

Mat black Enchace 90 Dual Multilink Adapter

F10 A

Mat black Enhance Multi-link for Acrylic OD 12mm

F10 B

Mat black Enhance Rotary 90 Multilink Adapter

F10 C

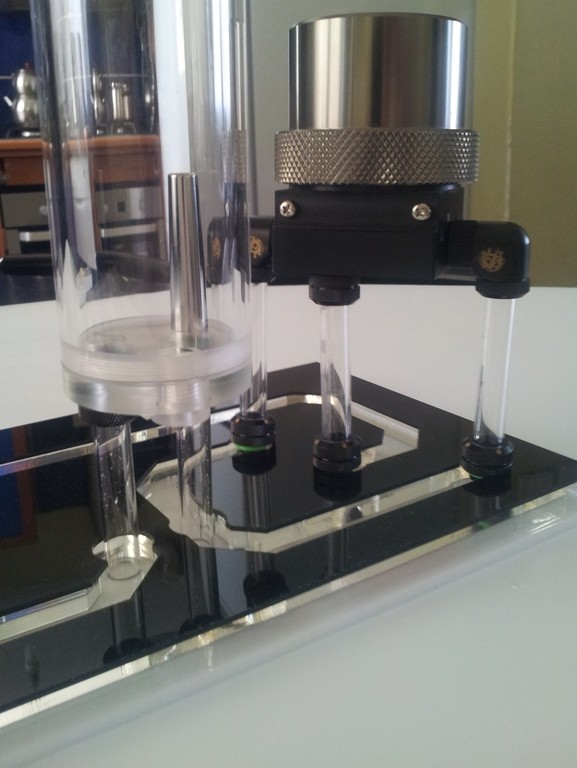

RESERVOIR : Bitspower Z Multi 250

F8A

POMP : Swiftech MCP 655

D6

MOD KIT: Bitspower D5

D12

INLINE TEMP. SENSOR:Aqua computer

D11

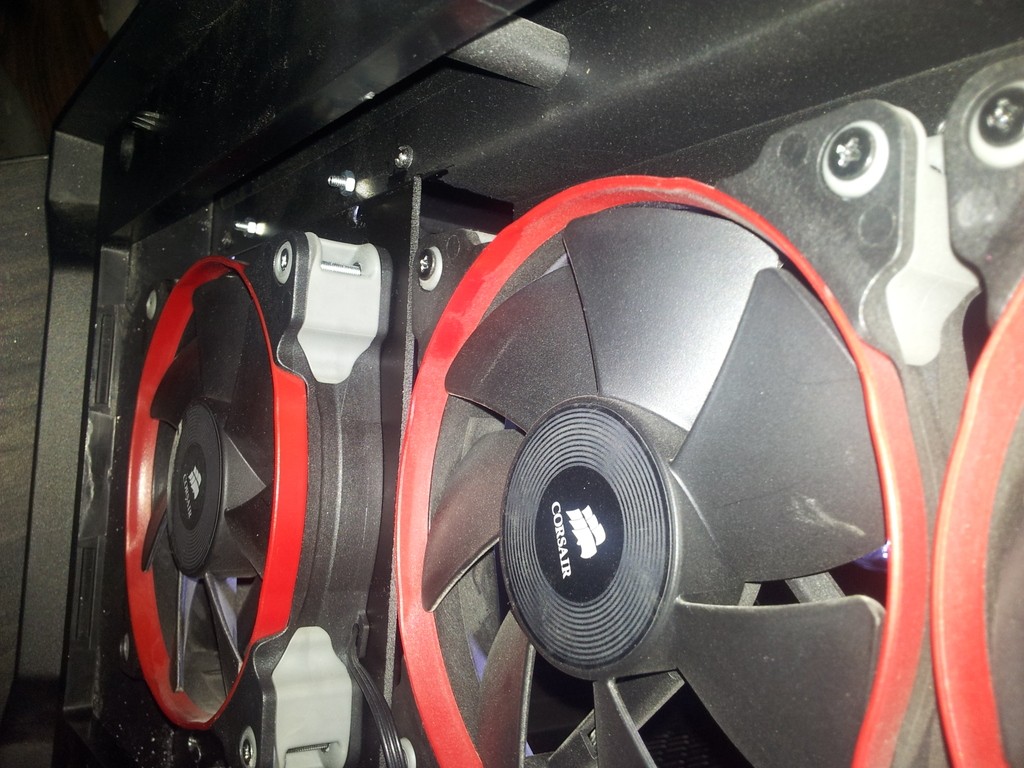

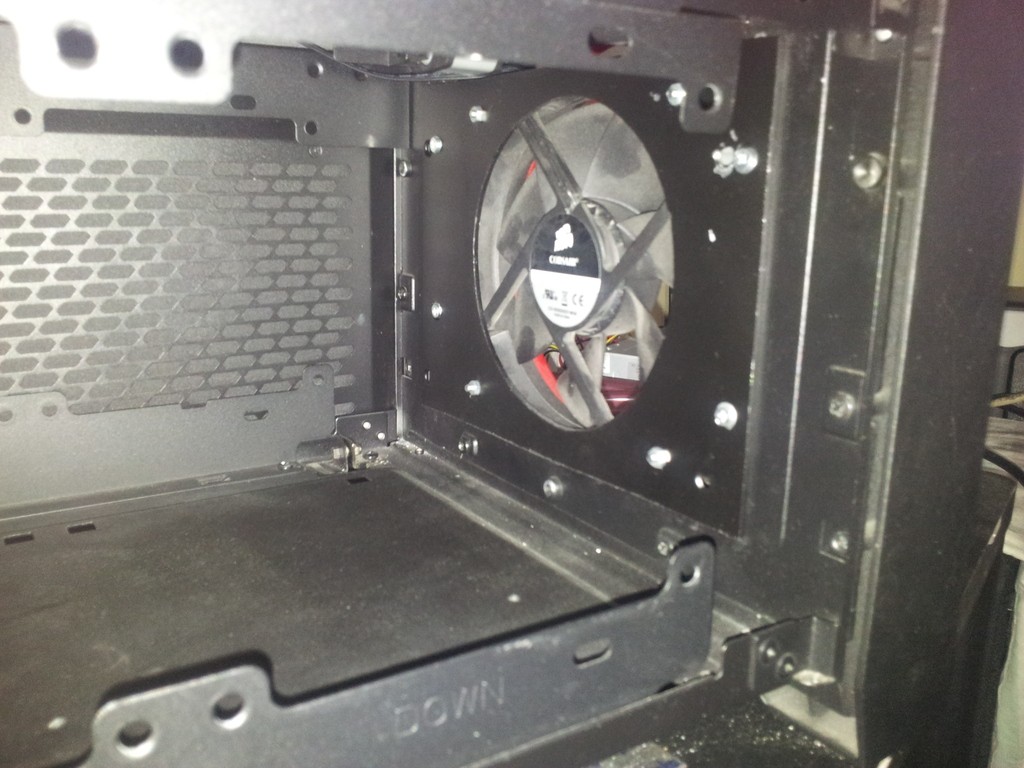

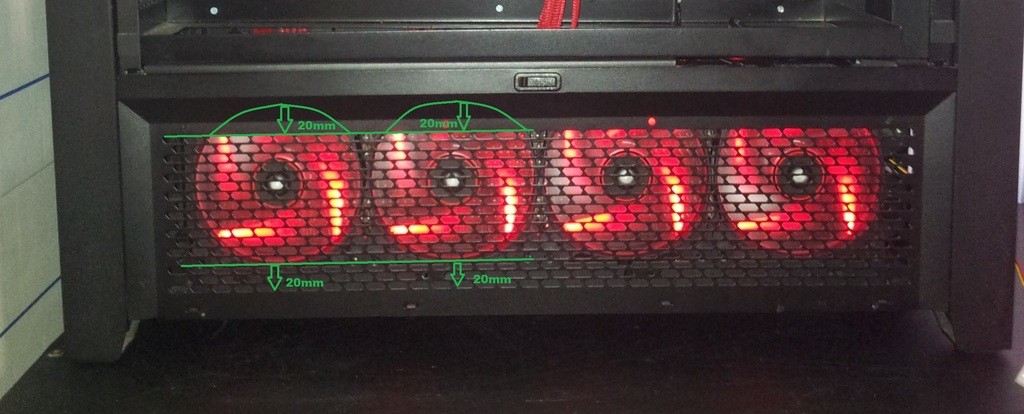

FANS: 4x Corsair SP 120 Perf. Edition

4x Corsair SP 120 LED-kırmızı

3x Corsair AF 120

PSU: Corsair AX 1200İ

D3

SSD: OCZ VERTEX 4 Sata III 512 GB

D4

SOUND CARD: ASUS Sound Blaster SBX

D7

FAN CONTROLLER : Lamptron CW 611

D5

Don t be angry , Mod photos are coming soon. arg-ist

I'm here again after a long illness vacation.

My SAK SAK 800D CASE was completed.

http://www.hardwareluxx.de/communit...-watercooled-copper-acrylic-pipe-1028332.html

Final Photos of MAC G5 CASE are comng soon.

http://www.hardwareluxx.de/community/f143/mac-g5-mod-arg-ist-1050219.html

And it is time to begin with a new Mod.

12 Angry Men SPIDER WEB Case

Again a 900D case… A nice case but with some with some shortcomings and errors. I do not know how many 900D case it was.

With the theme SPIDER WEB CASE.

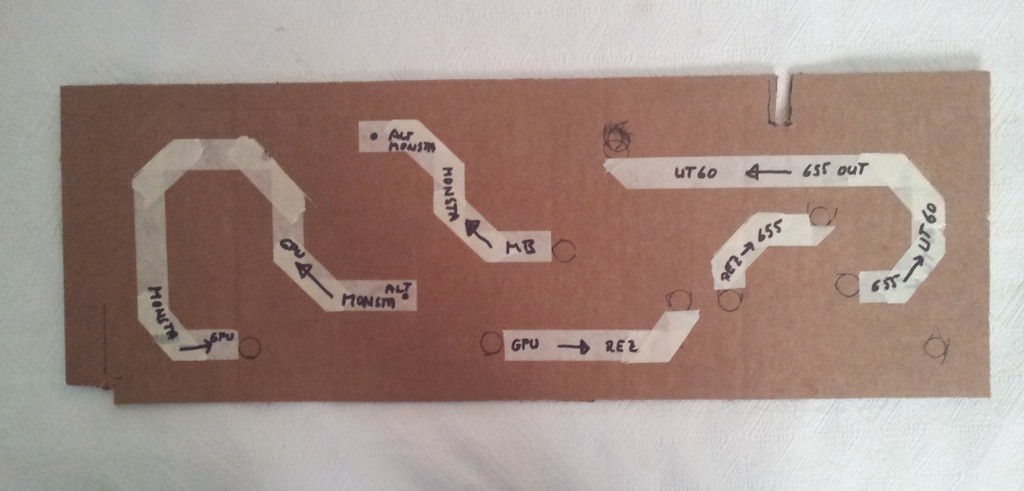

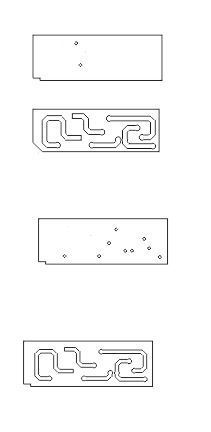

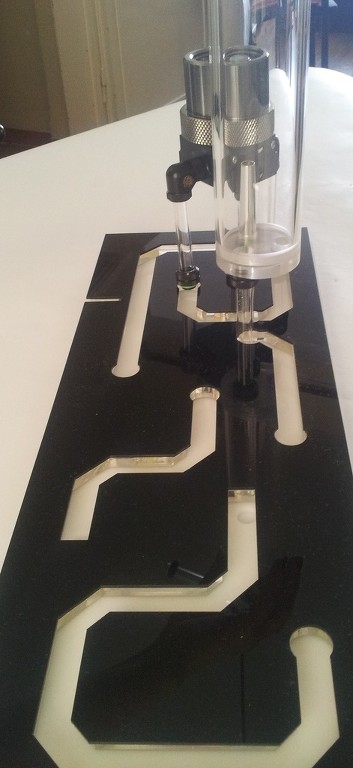

A1-

A2-

A3-

A4-

A5-

A6-

A7-

A8-

materials used at this case

CASE : Corsair 900D

D2

MB : Asus Rampage 5 extreme

D 10

CPU: İNTEL 5820 K

D14

RAM: CORSAIR DOMİNATOR PLATİNUM 4X8GB 3000

D13

VIDEO CARD :Evga 980 Classified

D8

D9

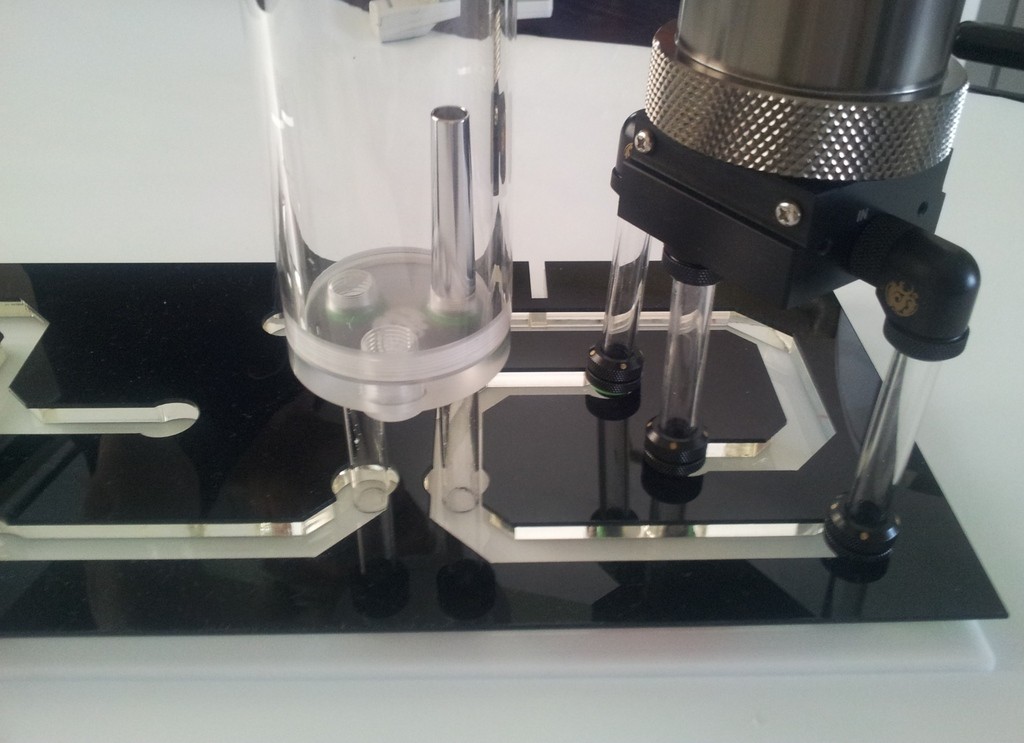

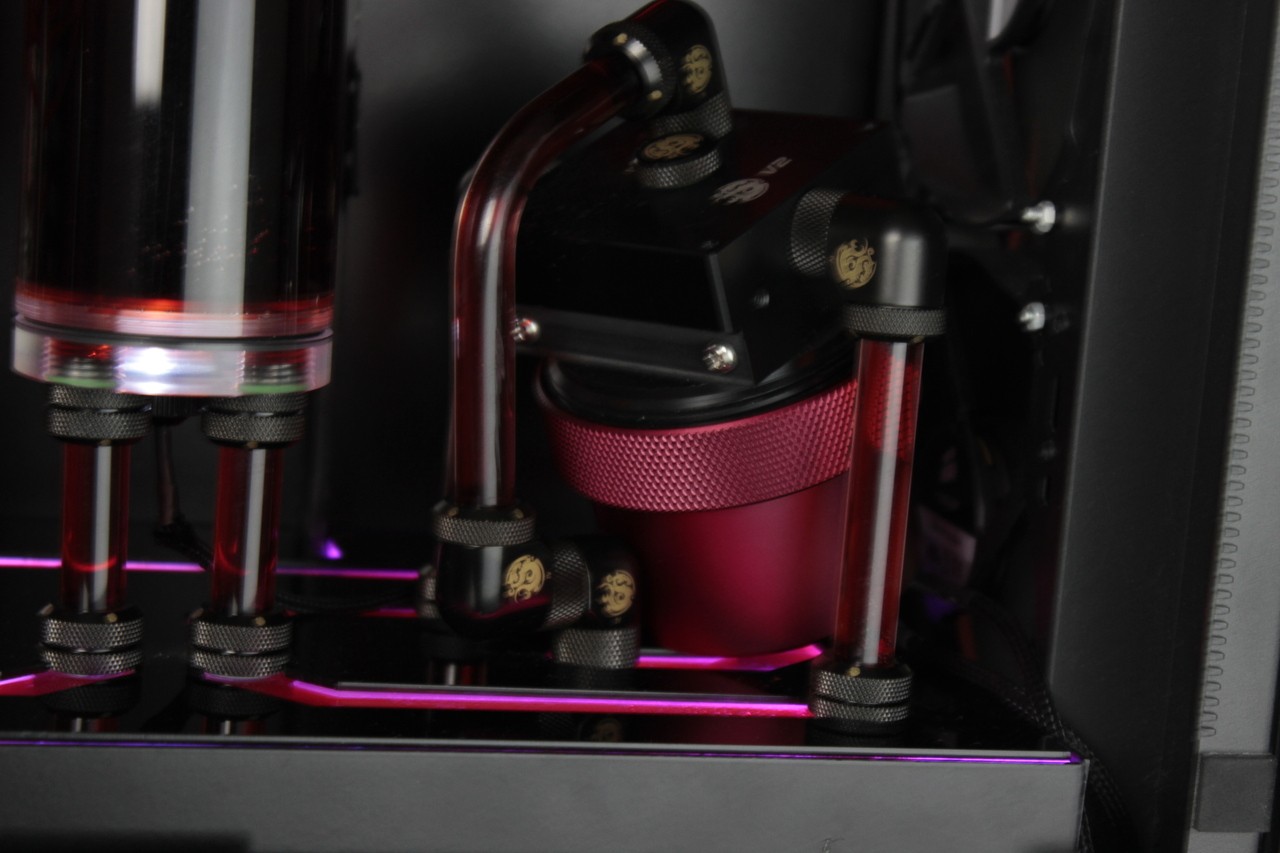

WATERCOOLING PARTS

RADIATORS: Alphacool UT60 480

Alphacool Monsta 480

D1

WB: EK

FITTINGS:

Mat black Enchace 90 Dual Multilink Adapter

F10 A

Mat black Enhance Multi-link for Acrylic OD 12mm

F10 B

Mat black Enhance Rotary 90 Multilink Adapter

F10 C

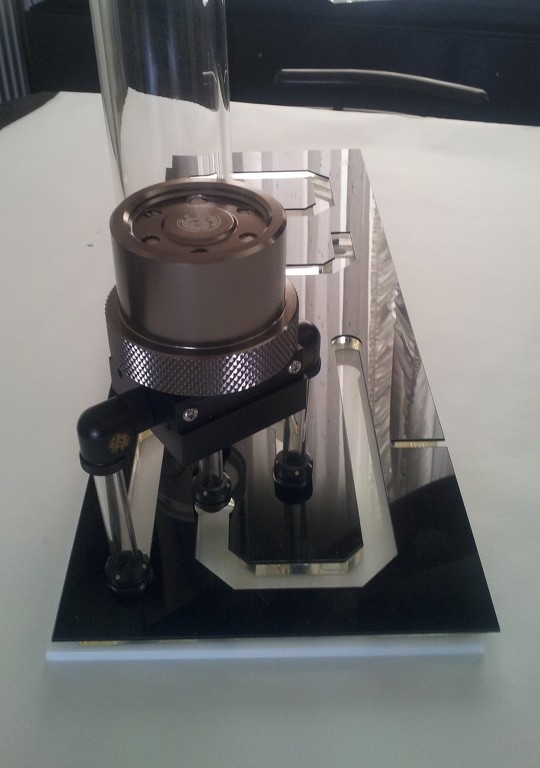

RESERVOIR : Bitspower Z Multi 250

F8A

POMP : Swiftech MCP 655

D6

MOD KIT: Bitspower D5

D12

INLINE TEMP. SENSOR:Aqua computer

D11

FANS: 4x Corsair SP 120 Perf. Edition

4x Corsair SP 120 LED-kırmızı

3x Corsair AF 120

PSU: Corsair AX 1200İ

D3

SSD: OCZ VERTEX 4 Sata III 512 GB

D4

SOUND CARD: ASUS Sound Blaster SBX

D7

FAN CONTROLLER : Lamptron CW 611

D5

Don t be angry , Mod photos are coming soon. arg-ist

Zuletzt bearbeitet: