bentleya

Neuling

XSPC Rasa

Intel 1366 Review

Intel 1366 Review

Introduction

After a few busy weeks testing heatsinks, it’s time to dust of the watercooling test bench. For many this will be the first time you have herd the words XSPC and Rasa in the same sentence so I’ll take this opportunity to be the first to introduce XSPC latest CPU waterblock.

It’s been just over a year and a half since XSPC released their latest flagship CPU waterblock the Delta V3. The Delta V3 took the place of the legendary and extremely popular Acrylic Edge and if you were lucky enough, one of the 15 Delrin Edge V2’s.

XSPC has always been a favorite for many, offering great cooling abilities with a price to match. But can this new block live up to the expectations of many? Sit tight, grab some popcorn and hopefully we can find out.

I would like to give a special thanks to Paul from XSPC, who got in contact with me and supplied this Pre Production sample of his new CPU waterblock.

Packaging & Contents

To get straight to the point there’s a few things to talk about regarding the XSPC packaging. It looks good while providing the right amount of protection for the product. I will talk about the latter of two in a few minutes.

The box design comes from the same current theme from XSPC, A Black slick multi folded rectangle box with an attractive red lighting pattern across the top and sides of the box. The box also includes the following; XSPC logo, website address, a list of the included items and a small sentence tucked away: which states the block has been individually Pressure Tested.

Once you get the box open the mounting hardware, backplates, thermal paste and installation Manual will be in the top of the box. However mine did not come with an installation manual as it was a pre production version, but you can view and download it from my server.

As I mentioned earlier one of the nice features with XSPC is the protection of the block while in shipping. The block sits in a 24mm thick foam surround and has a 12mm thick foam top.

Block Characteristics

You’ll probably be thinking to yourself by now as you read this, that XSPC has carried on the design and style of Delta series which has had a few minor and major changes to its design and looks over the years. But your wrong, XSPC has completely designed this new block from scratch and it’s the company first non-lateral flow CPU waterblock.

A few of the blocks key features:

•¼” BSP barb Holes

•Chrome Mounting Bracket

•Dimensions 50x50x19.5mm (WxDxH) (Without mounting bracket)

•Dimensions 95x95x19.5mm (WxDxH) (With mounting bracket)

•Weight 150 Grams

•Compatible with Intel Sockets 775, 1156 and 1366

•Chrome Mounting Bracket

•Dimensions 50x50x19.5mm (WxDxH) (Without mounting bracket)

•Dimensions 95x95x19.5mm (WxDxH) (With mounting bracket)

•Weight 150 Grams

•Compatible with Intel Sockets 775, 1156 and 1366

I must note that final version will have polished Chrome, Acetal and all the screws will be stainless Allen key head screws. These changes don’t affect the performance.

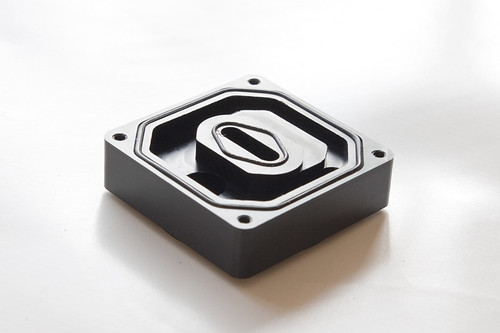

The block features a fully CNC machined Acetal top which has one inlet and one outlet 1/4” threaded barb holes, clearly marked by the engraved in and out. XSPC’s logo is also machined into the top in the same style as its recant blocks.

The top is also where all the water flow management goes on, water is directed though the inlet, which is forced though one large slot which measures 5x17mm. The water is then collected around the edge of the block and flows out the outlet.

The outlet design is nothing new and is seen on many blocks - however the way XSPC has machined the inlet is more exciting and something new. A 4.5x17.5mm slot as been machined from the side of block, which leads from the inlet to the center of the block. This design allows the inlet to be off centred and a greater chance of wider fittings being able to be used.

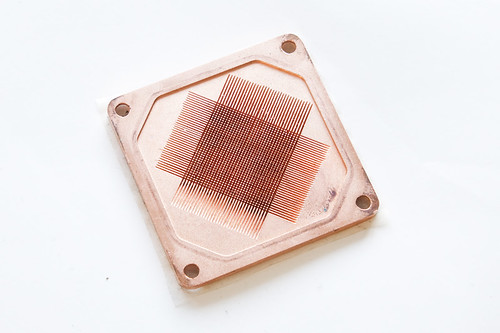

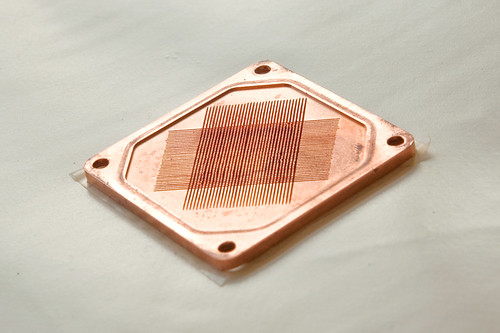

The base is machined out of 3mm thick copper and is flat. It features a 21x21mm diagonal micro pin matrix, the pins are 0.25 x 0.25mm and there are 1225 of them in total. The base comes with a clear plastic protection film that protects the base from scratches and dirt before use; remember to remove this before installing the block.

XSPC Generation Game

Let’s take a look back over the past two years and visualize the changes to the RASA from the Delta and Edge.

Compression Fitting Compatibility

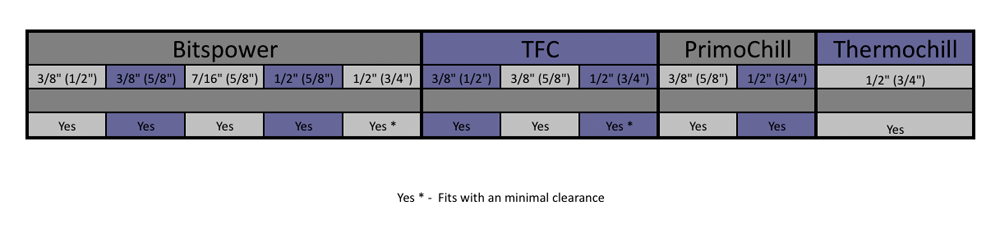

Over the past few years we have seen a great increase in the number of fittings available on the market, thanks to emerging companies like Bitspower. And with companies changing and adapting they ranges to suit the needs and the trends of modern watercooling. Modern compression fittings now come in many shapes, forms, colours and sizes. So let’s take a look at what fittings this block can handle.

Thermal Specification

A 5-mount test with 1hour with each mount, 40 minutes ‘warm up’ and 20 minutes of temperature logging.

•The 1366 Test Setup is as follows: Intel Core i7 920 D0 which is at stock 2.66GHz (no lapping) and at 4GHz (20x200MHz) when doing the overclocked tests. Running on a Gigabyte UD5 Extreme Motherboard. 6GB (3x2GB) of Patriot Viper DDR3 1600MHz Memory - the motherboard cooling is stock with no extra airflow. Video card is a BFG 9800GXS, also on stock cooling but the outer casing removed. The power comes from a Zalman 850W Modular PSU; Samsung 500GB hard drive split into 2x250 GB partitions. Test case is a Le Chuck Test Bench, which has horizontal mounting.

•The water cooling loop is as follows

•The thermal interface material (TIM) I use is MX-2 like most other enthusiasts and testers alike, with it working as soon as you apply it (no burn in time like AS5). Also being non conductive, conductive could become a problem with multiple applications per test and multiple coolers.

The TIM application method I use is the dot in the center. (Small pea sized dot applied to the center of the CPU, then when block is Compressed TIM is spread evenly across the cores of the CPU), Recorded data is only used if the TIM application is good after inspection on remount (my way of validating my results). The CPU is cleaned after every mount using Arctic Clean.

•I have 20 temperature probes across the test bench, 16 Dallas DS18B20 Digital one-wire sensors and 4 Intel DTS in the CPU.

•Temperature logging is recorded via my Crystalfontz 635, Using they WinTest V1.0 software for the Dallas one-wire sensors (Air). WinTest automatically logs temps and outputs them to .CSV files. OCCT V3.1.0 is used to log the core temps using the CPU’s built in DTS sensors, which are also automatically outputted to .CSV files. The .CSV are loaded in to Excel where the data in analyzed and interpreted into Graphs.

•The water cooling loop is as follows

oPump: I run a Laing DDC 1T with an XSPC res top, also known as the Swiftech MCP350, run at 12V. Controlled by a external bench PSU to minimize the risk of volt drop, a multi meter is used to monitor the volts

oRadiator: Alphacool NexXxoS Xtreme III 360mm Radiator with 3x Scythe S-FLEX SFF21D Fans @ 1200rpm. The fan is controlled via a Crystalfontz 635.

oLoop Order: Optimal to my needs, my loop is setup in this order, XSPC Res Top > DDC > Digmesa Flow Meter > 360mm Rad > Temp Sensor (Water In) > Ball Valve > Block Being Tested > Ball Valve > Temp Sensor (Water Out) > Res Top. (For an optimized loop for any set up always have your res feeding the pump.)

oRadiator: Alphacool NexXxoS Xtreme III 360mm Radiator with 3x Scythe S-FLEX SFF21D Fans @ 1200rpm. The fan is controlled via a Crystalfontz 635.

oLoop Order: Optimal to my needs, my loop is setup in this order, XSPC Res Top > DDC > Digmesa Flow Meter > 360mm Rad > Temp Sensor (Water In) > Ball Valve > Block Being Tested > Ball Valve > Temp Sensor (Water Out) > Res Top. (For an optimized loop for any set up always have your res feeding the pump.)

•The thermal interface material (TIM) I use is MX-2 like most other enthusiasts and testers alike, with it working as soon as you apply it (no burn in time like AS5). Also being non conductive, conductive could become a problem with multiple applications per test and multiple coolers.

The TIM application method I use is the dot in the center. (Small pea sized dot applied to the center of the CPU, then when block is Compressed TIM is spread evenly across the cores of the CPU), Recorded data is only used if the TIM application is good after inspection on remount (my way of validating my results). The CPU is cleaned after every mount using Arctic Clean.

•I have 20 temperature probes across the test bench, 16 Dallas DS18B20 Digital one-wire sensors and 4 Intel DTS in the CPU.

•Temperature logging is recorded via my Crystalfontz 635, Using they WinTest V1.0 software for the Dallas one-wire sensors (Air). WinTest automatically logs temps and outputs them to .CSV files. OCCT V3.1.0 is used to log the core temps using the CPU’s built in DTS sensors, which are also automatically outputted to .CSV files. The .CSV are loaded in to Excel where the data in analyzed and interpreted into Graphs.

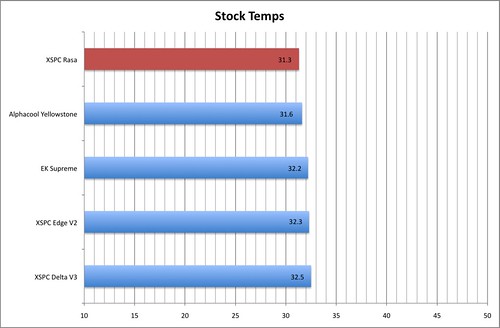

Thermal Test Results

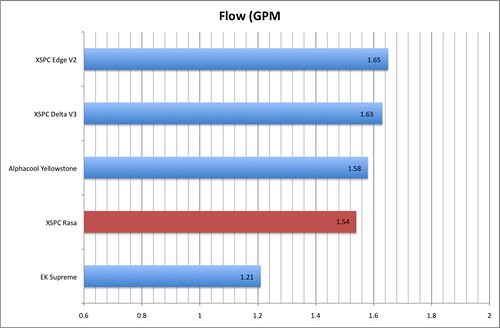

Flow Results

Conclusion & Final Thoughts

Pros

•¼” BSP thread barb ports for ultimate compatibility with G1/4” threaded barbs and fittings

• Easy to use mounting system

• Backplates provided for Intel 775, 1156 and 1366 platforms

• Multiple Intel platforms for increased compatibility

• Bitspower ½ x ¾ Compressions fit with under a millimeters gap

• Easy to use mounting system

• Backplates provided for Intel 775, 1156 and 1366 platforms

• Multiple Intel platforms for increased compatibility

• Bitspower ½ x ¾ Compressions fit with under a millimeters gap

Cons

• AMD users have to buy separate mounting plate, as there is no truly universal mounting plate. (AMD mounting will be avaible at a later date)

• Thermal Compound, other manufactures now include high end thermal past like MX2 instead of generic

• Thermal Compound, other manufactures now include high end thermal past like MX2 instead of generic

The new XSPC Rasa block is a great addition to XSPC product range. The package only has a few nibbles, with one being the generic thermal paste, which is included; we have seen a few other manufactures stepping up to the next level and including a high-end thermal paste. Hopefully this trend will continue in the future. The second thing, which caught my eye, was the aesthetics of the block - though it is a completely new block to the previous generations it still has an out dated look about it.

With taking in the fact this is a pre production version. The block should look fresher and more vibrant when the production versions are released.

However there are many positive things, which outweigh the negatives, such as the included backplates and the ability to install compression fittings without the need of 45’s. Its thermal performance is superb against some of its rivals even though they are more expensive.

Overall, the Rasa brings great performance for the price range and is a big step forward from the Delta series (although I hope XSPC don’t discontinue the Delta as it’s home is with multi block loops.) It also fills a gap in the market, between the high-end expensive blocks and the cheaper alternatives.

Zuletzt bearbeitet:

.

. .

.