patrick171

Enthusiast

Thread Starter

- Mitglied seit

- 22.08.2006

- Beiträge

- 2.706

Hallo Community,

in den letzten Monaten sorgte TFC für viel Aufregung durch ihre neue Admiral Radiatoren-Serie. Man wollte die Radiatoren-Welt "revolutionieren" und versprach viel. Bis auf ein paar Bilder und dem Video mit Dazmode gab es aber nicht viel Handfestes von TFC. Nun wird es jedoch interessant: hw-lab.com veröffentlichte vorgestern eine News über die deutsche Firma Thermalfins.

News: "Thermalfins — a new contribution to watercooling" von hw-lab.com

Practically all PC watercooling (WC) system can’t work properly without the help of radiator allowing efficient dissipation of heat and cooling down the heat carrier — water — inside the loop. Current WC radiator variety offers lots of models in different shapes and form factors (sizes). In general, WC radiators support installation of 1 to 4 on one side (2 to 8 for both side) while some models can have up-to 9 fans mounted (18 for both sides)!

Traditional WC radiator design features about dozen of tubes that are generally made of copper/brass with copper/aluminum fins located between it. All of this is put together in a solid radiator case (frame) with input/output ports arrange either on one or both ends of the frame. The ports have threads for fittings of appropriate size and attached tubing to be screwed into radiator. With fans installed and water running trough tube connected to rad, the last can now effectively transfer the heat from water in the loop into environment.

Despite the variety of available radiators, people using watercooling systems for their PCs, prefer models supporting 120mm fans. This is partially explained by a bigger availability of 120mm fans on market. However, during recent years the variety of 140mm fans and corresponding radiators have noticeably increased and already found its followers. Moreover, there are solutions capable of supporting both 120 and 140 millimeter fans at the same time, although the last one is a bit scarce. To change that situation, today, we are proud to introduce a totally different radiator line-up supporting 120 and 140mm fans and featuring some cool design options — Thermalfins (note: The web-page is under construction).

Thermalfins radiators are designed and made by German company Lötters Metallwaren GmbH that specializes in metalwork and heat-transfer. The company started nearly 30 years ago with the development and production of heating components, like convection-grids and burners, guide rails and ceran-units for heating and cooking industries. Now company can boast of orders placed by Viessmann GmbH&Co KG, Küppersbusch GmbH, Oranier Heiztechnik, and other firms, including well-known auto-giant Audi. Heat transfer was and still remains the main business area of the company. The company uses the latest laser technologies for high precision and top efficiency of manufactured products. Other manufacturing technologies used by Lötters Metallwaren GmbH are: welding of any type including 3D-Laser welding of materials up-to 4000mm long, pressing up-to 150 tons, sawing to a max length of 6000mm. This equipment is used for machining materials like extruded aluminum, stainless-steel, tubes, wires, plates and different profiles. Finally you can have you product anodized or power-coated for a nice finish look.

Thermalfins are the first ever radiators designed and produced by Lötters Metallwaren GmbH and experience in heat-transfer was the basic knowledge to develop this product. The material, these radiators are made of, is aluminum and stainless-steel. One of the reasons to do so is to get this rads compatible with ROHS-certificates that prohibit using lead (Pb) or no Cadmium (Cd) in manufacturing process. And there is no need to worry about electro-chemical erosion, since wetted parts are not made of aluminum but steel instead. Moreover, tubes have inner structure which allows an optimal thermal transfer to the outside aluminum-fins. Though copper is definitely better than steel in terms of heat conductance, the steel layer is so thin (only 0,2mm) that it only requires to provide a thermal breakthrough to the aluminum, which is mostly dependent on physical inertia, therefore, the heat of the coolant is moving right through to the alu-fins.

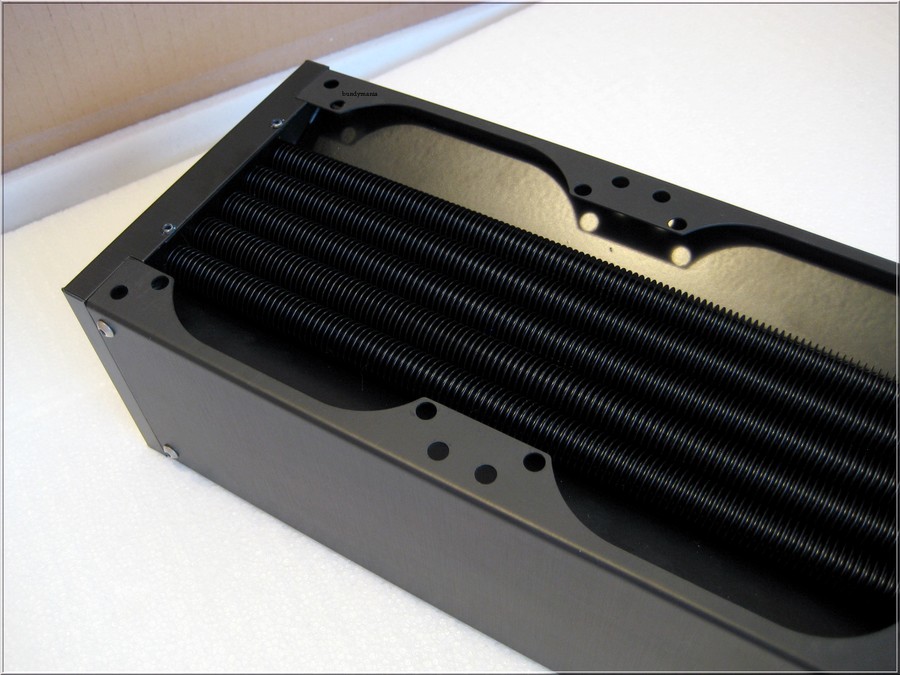

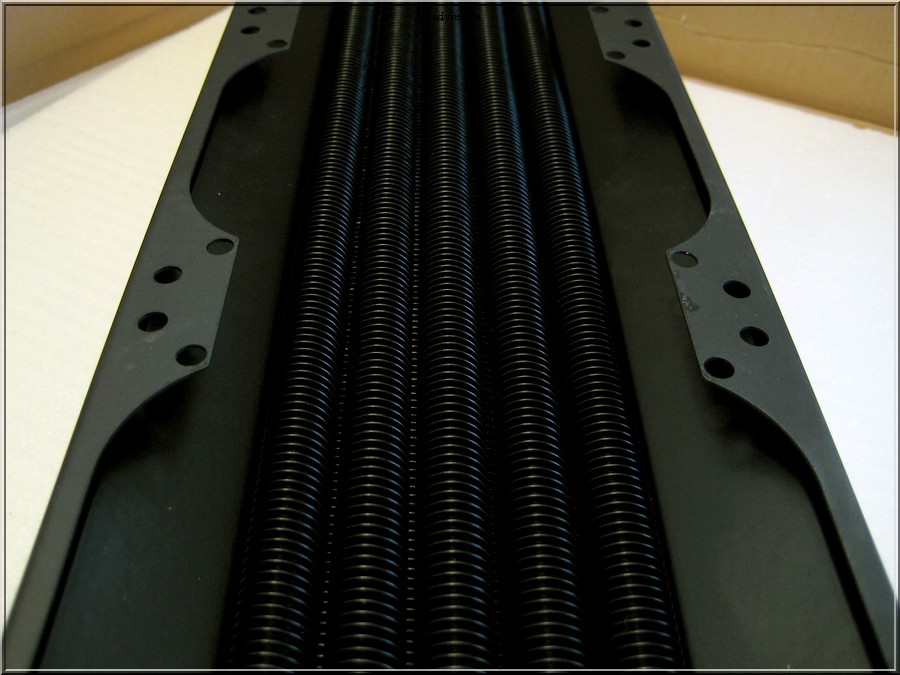

Unlike traditional WC radiators with rectangular-shaped tubes that are a bit smaller in width than the actual thinness of the rad, Thermalfins radiators have narrow round tubes arranged in chessboard order. This is said to bring great cooling performance and reduce noise of the air stream generated by fans. As for fan speed, manufacturer claims these rads to operate well both with High and Low speed models. All tubes are laser welded to a basic-plate whereas the last one is covered with the waterchannels. Radiator frame is made of Aluminum to bring lots of design options. Anodized aluminum is a high grade surface, with the possibility of different colors and its lightweight too.

Another difference with traditional WC rads is waterflow. Traditional ones use parallel U-pass waterflow. That means, when water enters the rad the waterflow is then split into several parallel ones inside the rad. At the other end of the rad waterflows are collected in a small water chamber and again spitted into several parallel ones on its way back following U-shape water movement principle. This cooling design has several drawbacks that reduces the overall cooling efficiency of the rad. First off all, its is not a secret that water take the easiest way to move trough obstacles, that is, the rad. Therefore, water inside each tube of traditional WC rad does not move with an equal flow rate. On the other hand, Thermalfins radiators use sequential waterflow! with water running from one tube to another one thus providing one flow rate value for all tubes to improve the heat exchange significantly.

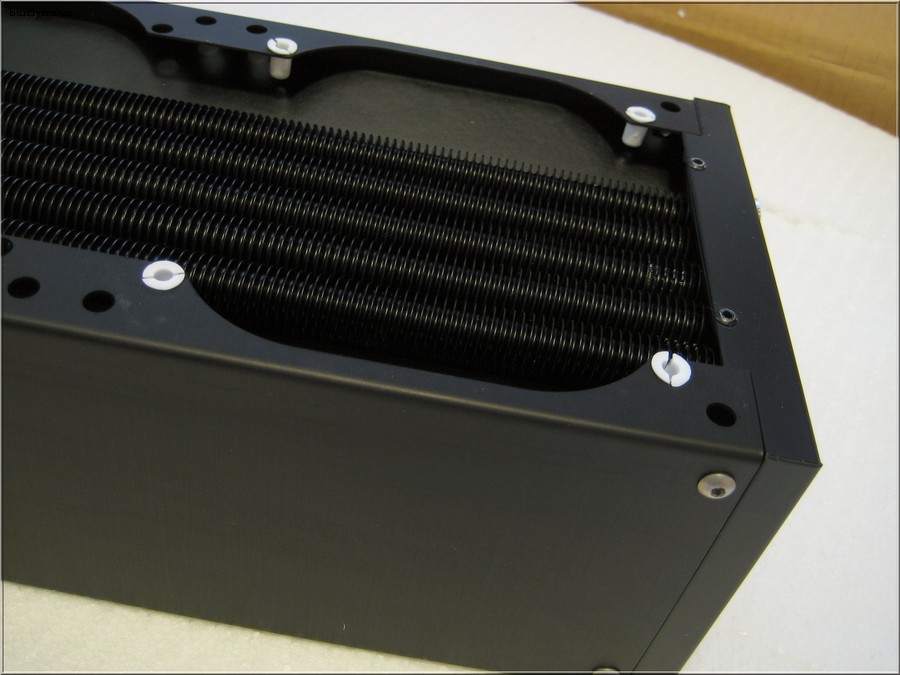

Now let us talk about the model we hare received in details. Thermalfins X3 is a triple radiator supporting both 120 and 140 mm fans (fan spacing 15mm). The “X” stand for eXtreme line-up as this rads are 105 mm thick. Twenty three watertubes with 14.8mm Outside Diameter (OD) and 8mm Inside Diameter (ID) form the cooling core of the rad. The tubes can hold pressure up-to 5 Bars (secure tested 10 Bars). The cooling core is a bit smaller than black anodized radiator frame. In fact, its is 418mm(H) x 80mm(W) x 75mm(D) for a radiator, sized: 445mm(H) x 144mm(W) x 105mm(D). That is quite unusual compared to traditional WC rads where fins cover almost all frame area. However, Thermalfins radiators have detachable side panels! that hide the reason for such a noticeable difference.

Underneath it you can see two metal plates forming some kind of airflow collector which reminds me of a 140 mm to 120 mm fan adapters. Those plates work as baffle-plates to brings the airflow from fans in the right direction. We don’t know how will it effect radiator performance with 140mm fans but it should work quite well for 120mm fans. You can also notice that now, you won’t have a chance to puncture your rad tube accidentally, as with screws too long the last will hit those baffle-plates instead of watertube.

Some of you might already noticed that side panels are quite thin and have fan mounting holes larger than needed for M3 or M4 (or American equivalent of this thread sizes) screws. And there is a good reason for that: these radiators use what is called “thread-inserts”.

Basically it is a plastic insert that holds M4 metal thread inside. The insert fits mounting holes with a small pressure and sits there tight enough to properly install a fan. Since “thread-inserts” is about 9mm high this will effect the length of screws needed for fan mounting. Surprisingly, we have not found any mounting screws with the rad. This can be explained by the fact that this is an engineering sample. But we are sure, that first lucky owners of new Thermalfins X3 radiators will have all requiring mounting hardware in place. Back to inserts, there 24 of them, which is enough to mount up-to six fans (for push/pull setups). In case of a damage, “thread-inserts” can be replaced as these will also be available for purchase. As you see, the fans are not touching the radiator, but the inserts itself. This is said to reduce vibrations between radiator and fans. Further more, final product will include silicon-pads too.

I have tried “thread-inserts” and i must say they work pretty well. For mounting 38mm think fans I used 50mm M4 screws. And as you will see in the picture below this is fairly enough. I must say that pulling out “thread-inserts” is a bit tricky, however, i managed to do it without damaging any of them.

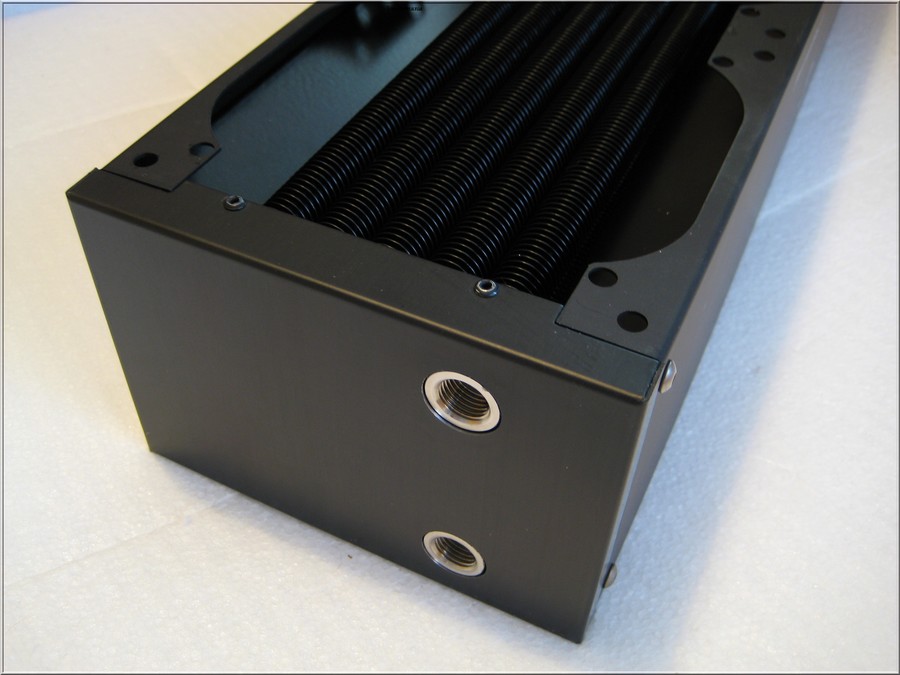

The sample we have received has two G1/4 treated ports (upgradable to four on request) on the top of the rad which is yet another difference with traditional rads that mostly have inputs/outputs located on side. Top located ports provide direct tube connection, which sometimes is not very convents in terms of tube routing, however, Thermalfins X3 is about 40mm shorter than traditional 140×3 rads (ThermoChill PA140.3 is 480mm long). So with the help of angled fittings or tubing bent at 90 degrees you will have the rad of same or even less size as, for example, ThermoChill PA140.3 radiator.

Another thing to note, Thermalfins X3 has feet! That right, the package contains four rubber feet that can be mounted to either of side panels. If you won’t use these with rad you can find them useful somewhere else, for example, silencing the pump or your noisy hard drive or even HDD cage.

Manufacturer underlines that Thermalfins is a very customizable product and besides fixed-size versions there will be custom-made radiators with different dimensions and colors to meet particular requirements of customers. As an example, take a look at grey side panels that was sent to us with the rad.

Specification of Thermalfins X-series rads are as follows:

X-series radiators are already in full-scale production and will be available from March 2011 at Thermalfins e-shop, followed by Xs line-up presented in April. As for future plans, manufacturer states to present passively cooled rads as well as combination of both passive and active systems.

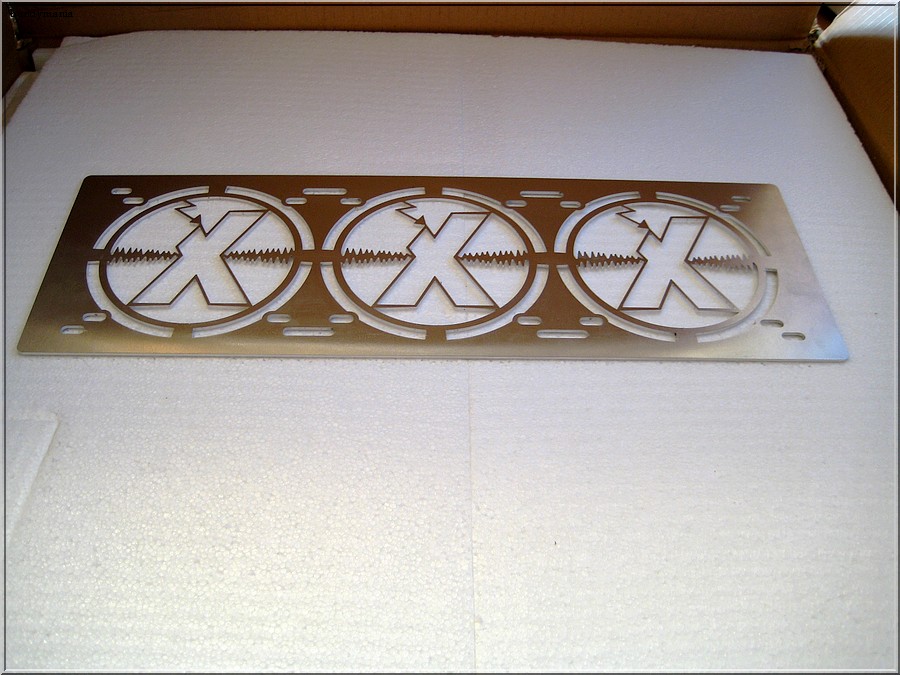

As an exclusive partner of Thermalfins we will have a full-fledged line up of “X”-series radiators previewed soon. This includes some other products that are preparing to launch, for example, radiator grills.

That is all for now. The rad will be tested in our lab and results will be published as soon as possible. So stay tuned!

_____________________________

Quelle: hw-lab.com

Traditional WC radiator design features about dozen of tubes that are generally made of copper/brass with copper/aluminum fins located between it. All of this is put together in a solid radiator case (frame) with input/output ports arrange either on one or both ends of the frame. The ports have threads for fittings of appropriate size and attached tubing to be screwed into radiator. With fans installed and water running trough tube connected to rad, the last can now effectively transfer the heat from water in the loop into environment.

Despite the variety of available radiators, people using watercooling systems for their PCs, prefer models supporting 120mm fans. This is partially explained by a bigger availability of 120mm fans on market. However, during recent years the variety of 140mm fans and corresponding radiators have noticeably increased and already found its followers. Moreover, there are solutions capable of supporting both 120 and 140 millimeter fans at the same time, although the last one is a bit scarce. To change that situation, today, we are proud to introduce a totally different radiator line-up supporting 120 and 140mm fans and featuring some cool design options — Thermalfins (note: The web-page is under construction).

Thermalfins radiators are designed and made by German company Lötters Metallwaren GmbH that specializes in metalwork and heat-transfer. The company started nearly 30 years ago with the development and production of heating components, like convection-grids and burners, guide rails and ceran-units for heating and cooking industries. Now company can boast of orders placed by Viessmann GmbH&Co KG, Küppersbusch GmbH, Oranier Heiztechnik, and other firms, including well-known auto-giant Audi. Heat transfer was and still remains the main business area of the company. The company uses the latest laser technologies for high precision and top efficiency of manufactured products. Other manufacturing technologies used by Lötters Metallwaren GmbH are: welding of any type including 3D-Laser welding of materials up-to 4000mm long, pressing up-to 150 tons, sawing to a max length of 6000mm. This equipment is used for machining materials like extruded aluminum, stainless-steel, tubes, wires, plates and different profiles. Finally you can have you product anodized or power-coated for a nice finish look.

Thermalfins are the first ever radiators designed and produced by Lötters Metallwaren GmbH and experience in heat-transfer was the basic knowledge to develop this product. The material, these radiators are made of, is aluminum and stainless-steel. One of the reasons to do so is to get this rads compatible with ROHS-certificates that prohibit using lead (Pb) or no Cadmium (Cd) in manufacturing process. And there is no need to worry about electro-chemical erosion, since wetted parts are not made of aluminum but steel instead. Moreover, tubes have inner structure which allows an optimal thermal transfer to the outside aluminum-fins. Though copper is definitely better than steel in terms of heat conductance, the steel layer is so thin (only 0,2mm) that it only requires to provide a thermal breakthrough to the aluminum, which is mostly dependent on physical inertia, therefore, the heat of the coolant is moving right through to the alu-fins.

Unlike traditional WC radiators with rectangular-shaped tubes that are a bit smaller in width than the actual thinness of the rad, Thermalfins radiators have narrow round tubes arranged in chessboard order. This is said to bring great cooling performance and reduce noise of the air stream generated by fans. As for fan speed, manufacturer claims these rads to operate well both with High and Low speed models. All tubes are laser welded to a basic-plate whereas the last one is covered with the waterchannels. Radiator frame is made of Aluminum to bring lots of design options. Anodized aluminum is a high grade surface, with the possibility of different colors and its lightweight too.

Another difference with traditional WC rads is waterflow. Traditional ones use parallel U-pass waterflow. That means, when water enters the rad the waterflow is then split into several parallel ones inside the rad. At the other end of the rad waterflows are collected in a small water chamber and again spitted into several parallel ones on its way back following U-shape water movement principle. This cooling design has several drawbacks that reduces the overall cooling efficiency of the rad. First off all, its is not a secret that water take the easiest way to move trough obstacles, that is, the rad. Therefore, water inside each tube of traditional WC rad does not move with an equal flow rate. On the other hand, Thermalfins radiators use sequential waterflow! with water running from one tube to another one thus providing one flow rate value for all tubes to improve the heat exchange significantly.

Now let us talk about the model we hare received in details. Thermalfins X3 is a triple radiator supporting both 120 and 140 mm fans (fan spacing 15mm). The “X” stand for eXtreme line-up as this rads are 105 mm thick. Twenty three watertubes with 14.8mm Outside Diameter (OD) and 8mm Inside Diameter (ID) form the cooling core of the rad. The tubes can hold pressure up-to 5 Bars (secure tested 10 Bars). The cooling core is a bit smaller than black anodized radiator frame. In fact, its is 418mm(H) x 80mm(W) x 75mm(D) for a radiator, sized: 445mm(H) x 144mm(W) x 105mm(D). That is quite unusual compared to traditional WC rads where fins cover almost all frame area. However, Thermalfins radiators have detachable side panels! that hide the reason for such a noticeable difference.

Underneath it you can see two metal plates forming some kind of airflow collector which reminds me of a 140 mm to 120 mm fan adapters. Those plates work as baffle-plates to brings the airflow from fans in the right direction. We don’t know how will it effect radiator performance with 140mm fans but it should work quite well for 120mm fans. You can also notice that now, you won’t have a chance to puncture your rad tube accidentally, as with screws too long the last will hit those baffle-plates instead of watertube.

Some of you might already noticed that side panels are quite thin and have fan mounting holes larger than needed for M3 or M4 (or American equivalent of this thread sizes) screws. And there is a good reason for that: these radiators use what is called “thread-inserts”.

Basically it is a plastic insert that holds M4 metal thread inside. The insert fits mounting holes with a small pressure and sits there tight enough to properly install a fan. Since “thread-inserts” is about 9mm high this will effect the length of screws needed for fan mounting. Surprisingly, we have not found any mounting screws with the rad. This can be explained by the fact that this is an engineering sample. But we are sure, that first lucky owners of new Thermalfins X3 radiators will have all requiring mounting hardware in place. Back to inserts, there 24 of them, which is enough to mount up-to six fans (for push/pull setups). In case of a damage, “thread-inserts” can be replaced as these will also be available for purchase. As you see, the fans are not touching the radiator, but the inserts itself. This is said to reduce vibrations between radiator and fans. Further more, final product will include silicon-pads too.

I have tried “thread-inserts” and i must say they work pretty well. For mounting 38mm think fans I used 50mm M4 screws. And as you will see in the picture below this is fairly enough. I must say that pulling out “thread-inserts” is a bit tricky, however, i managed to do it without damaging any of them.

The sample we have received has two G1/4 treated ports (upgradable to four on request) on the top of the rad which is yet another difference with traditional rads that mostly have inputs/outputs located on side. Top located ports provide direct tube connection, which sometimes is not very convents in terms of tube routing, however, Thermalfins X3 is about 40mm shorter than traditional 140×3 rads (ThermoChill PA140.3 is 480mm long). So with the help of angled fittings or tubing bent at 90 degrees you will have the rad of same or even less size as, for example, ThermoChill PA140.3 radiator.

Another thing to note, Thermalfins X3 has feet! That right, the package contains four rubber feet that can be mounted to either of side panels. If you won’t use these with rad you can find them useful somewhere else, for example, silencing the pump or your noisy hard drive or even HDD cage.

Manufacturer underlines that Thermalfins is a very customizable product and besides fixed-size versions there will be custom-made radiators with different dimensions and colors to meet particular requirements of customers. As an example, take a look at grey side panels that was sent to us with the rad.

Specification of Thermalfins X-series rads are as follows:

X-series radiators are already in full-scale production and will be available from March 2011 at Thermalfins e-shop, followed by Xs line-up presented in April. As for future plans, manufacturer states to present passively cooled rads as well as combination of both passive and active systems.

As an exclusive partner of Thermalfins we will have a full-fledged line up of “X”-series radiators previewed soon. This includes some other products that are preparing to launch, for example, radiator grills.

That is all for now. The rad will be tested in our lab and results will be published as soon as possible. So stay tuned!

_____________________________

Quelle: hw-lab.com

Liest man die News und schaut sich die Bilder an, fallen gravierende Gemeinsamkeiten mit den Admiral-Radiatoren von Feser auf. Es kommt sogar die Vermutung auf, dass TFC und die Personen hinter Thermalfins gemeinsam die Admiräle entwickelt haben. Unterstützt wird dies jedenfalls durch folgendes Zitat von unserem Wakü-Guru bundymania im XS-Forum:

Zitat: bundymania, "Feser's New Lineup"-Thread, XS-Forum

Exact this happens now, a guy from the company wrote:

TFC tried to twit me on the worst way…! There´s no patent owned by TFC…because…a contract has to be signed ( this contract was done by the patent attorney )…this contract should arrange the cooperation between TFC and me…and after all was done, TFC didn´t sign it !

But what about Admiral Rads...and FrozenCPU...which was investing 30.000 $ in the new Rad Series ? Hey Mark, pls tell us some details, what is going on.

Vergleich: TFC Admiral - Thermalfins X:

- neue Bauweise: Sowohl die Feser Admiral Radiatoren als auch Thermalfins X Radiatoren basieren auf einem Röhren-Prinzip. TFC nannte dieses Röhren einfach Tubes. Sie bestehen aus einem hauchdünnen Edelstahlrohr, welches von eloxiertem Aluminium mit entsprechender Kühlstruktur ummantelt ist.

TFC und Thermalfins rechtfertigen diese Bauweise praktisch mit gleicher Wortwahl:

Auszug aus der hw-lab.com News "Feser Admiral radiators — facts only". (Anmerkung: News nicht mehr online!):

hw-lab.com: Can you tell us about materials that are used in the production of these radiators?

>> Feser: The material, these radiators are made of, is aluminum and stainless-steel. The first reason was, to get this rads done in compliance with ROHS-confirmation. No lead (Pb) and no Cadmium (Cd) inside. But there´s no aluminum in the water-channels! The water-bearing parts are made of a really fine stainless tube, with an inside structure, which allows an optimal thermal transfer to the outside aluminum-fins. Everyone knows about the heat conductance of copper and we all know, that stainless steel is worse than copper. But, in this case we only need a thermal breakthrough to the aluminum and that’s mostly dependent on physical inertia. The wall-thickness of the stainless tube is only 0,2mm. So, the heat of the coolant is moving right through to the alu-fins…

Auszug aus der hw-lab.com News "Thermalfins — a new contribution to watercooling".:

The material, these radiators are made of, is aluminum and stainless-steel. One of the reasons to do so is to get this rads compatible with ROHS-certificates that prohibit using lead (Pb) or no Cadmium (Cd) in manufacturing process. And there is no need to worry about electro-chemical erosion, since wetted parts are not made of aluminum but steel instead. Moreover, tubes have inner structure which allows an optimal thermal transfer to the outside aluminum-fins. Though copper is definitely better than steel in terms of heat conductance, the steel layer is so thin (only 0,2mm) that it only requires to provide a thermal breakthrough to the aluminum, which is mostly dependent on physical inertia, therefore, the heat of the coolant is moving right through to the alu-fins.

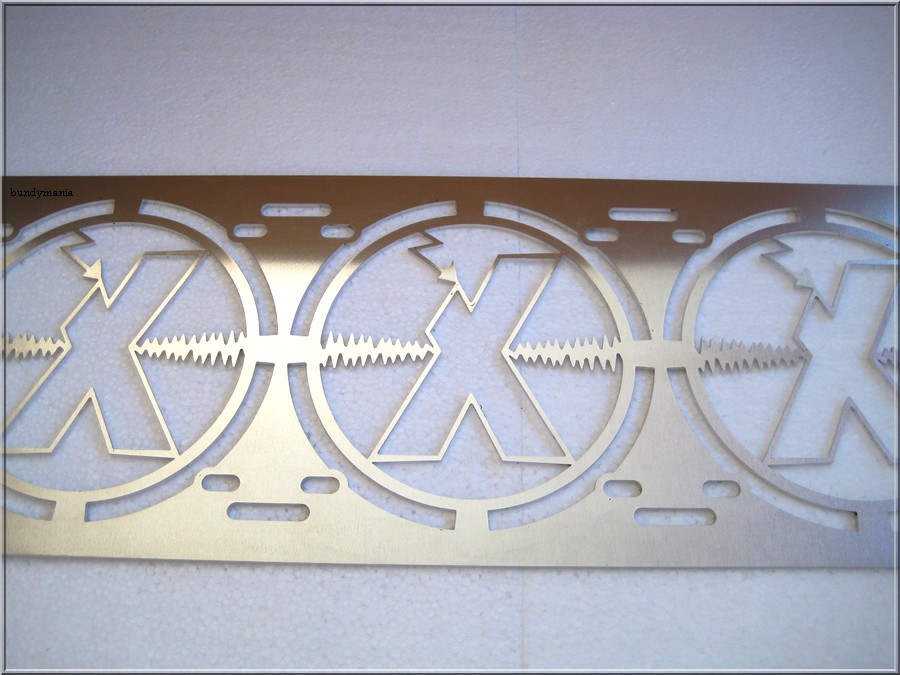

Bilder dazu:

TFC:

Thermalfins:

- Wasserfluss: Bei der Art und Weise, wie die einzelnen Röhren durchströmt werden, nehmen sich beide Radiator-Serien wieder nicht viel. Wie schon bei den alten Watercool HTF3 Radiatoren wird eine Röhre nach der anderen durchströmt. Da Thermalfins jedoch nicht auf eine modulare Bauweise setzt, unterschieden sich die Radiatoren dann doch ein wenig. So sind die "Umlenkstellen" bei den X-Radiatoren von Thermalfins mit einer Edelstahlplatte bedeckt und verschweißt. FTC setzt oder setzte hier auf spezielle Delrin/Acetal-Bauteile, die gefräste Kanäle zum Umlenken verwenden.

Thermalfins setzt im Gegensatz zu TFC jedoch auf eine andere Anordnung der Tubes oder Röhren im Radiator. Bei den X-Radiatoren sind fünf Röhren sehr eng beieinander in der Mitte platziert. Den restlichen Platz nehmen "Luftleitbleche" ein, die die Luft der 120- bzw. 140mm Lüfter in Richtung der Röhren leiten. Vergleicht man die Bilder, so scheint es, als hätte TFC die Röhren über die ganze Breite verteilt.

Bilder dazu:

TFC:

Thermalfins:

Update 1: Tom von Thermalfins hat sich in deutsch in den Kommentaren zur hw-lab.com News geäußert:

[...] Vielen ist die Vorgeschichte der Radiatoren bekannt…und ich möchte auch nicht weiter auf dieses

“düstere Kapitel einer Kooperation” eingehen. Die Ähnlichkeit der Radiatoren kommt also nicht von ungefähr…haben ja schließlich ein “Elternhaus” [...]

Damit ist bestätigt, dass beide Radiatoren-Serien den gleichen Ursprung haben. Interessant dürfte nun sein, ob TFC die Admiräle überhaupt noch verkaufen wird.

Update 2: Wakü-Guru bundymania hat ein Testmuster erhalten - umfangreicher Test kommt bald

mehr Bilder:

Zuletzt bearbeitet: