Do you have a Noctua Secufirm 2 bracket available? (from NH-D15 air cooler?).

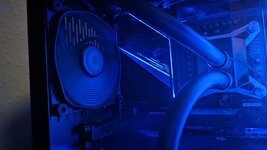

I think you can use this with Liquid Freezer II 360 or 420 AIO.

I already tested Secufirm 2 backplate with Eisbaer Extreme 280 AIO--(Eisbaer backplate is horrible--please never use this abortion abomination!) it is hard to get the thumbscrews (noctua screws) into the bolts, but you can do it with some pressure.

Then the contact pressure (downwards) will be very, very strong.

I did not test secufirm2 with Liquid Freezer II yet, but I think it will work (both 1700 and 1151 Secufirm versions will work if the other one does).

If you want super temps: With Thermalright Frame, Delid IHS, replace solder with liquid metal, sand UNDERSIDE EDGES OF IHS down about 0.2mm (to compensate for indium removal z-height), then replace IHS, use liquid metal on CPU die core and underside of IHS (contact area to die, both surfaces must be painted with liquid metal because LM needs tension on both sides!) AND then lightly sand top side of IHS to copper shining (to make it flatter), then re-lid the IHS, then also apply liquid metal on top of the IHS also (Danger--please apply kapton tape around the aluminum anti-bend thermalright frame because liquid metal can destroy aluminum, first!!!!, and do not apply LM edge to edge of IHS if you are using thermalright frame, leave 0.3mm distance from edge), you can probably get temps 20C lower than original IHS and solder.

This mod would be better with Secufirm 2 backplate than with Arctic backplate because you can increase the mounting pressure for the liquid metal.

kommt in der regel beim ersten start^^

kommt in der regel beim ersten start^^ ka ob das nen einfluss hat

ka ob das nen einfluss hat

weiter hab ich kein savestand ^^

weiter hab ich kein savestand ^^